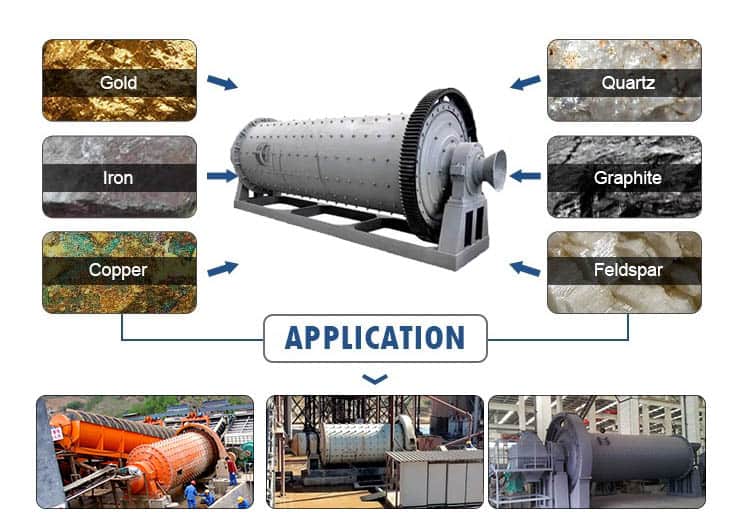

Ball mill is the key equipment for crushing materials after it is crushed. Ball mill can grinding granite, quartz stone, fluorite, gold ore, copper ore, iron ore, lithium faience, hematite, high alumina ceramics, iron powder, magnetic pyrite, glass and so on more than 200 kinds of materials for dry grinding or wet grinding.

Application Fields of Ball Mill

Ball mill is widely used in mineral processing, ore beneficiation plant, cement plant, building materials, refractory materials, silicate products, glass ceramics, chemical industry and other industries.

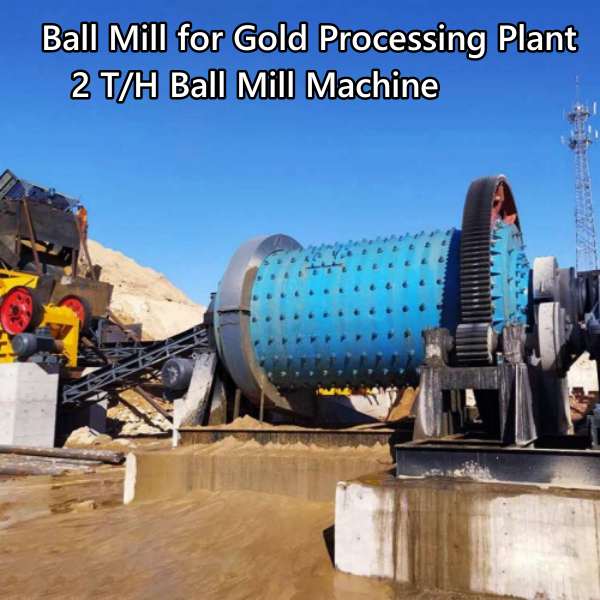

Hot types: wet ball mill, dry ball mill

Hot models: Ф1200×2400, Ф1830×3000, Ф2100×4500

Hot capacity: 1.5 - 5t/h, 4 -10t/h, 12 - 50t/h

Zoomjo- Ball Mill Price

Factory direct sale with low cost. Zoomjo Group has 40 years of experience of ball mill manufacturing. We can different customised ball mill types to meet your needs.

Please tell us your requirements and we will send you detailed ball mill equipment price list within 1 hour via Whatsapp or email!

The motor drives the rotating cylinder to drive the internal grinding media (such as steel balls) and the material to move together. When the cylinder rotates, the medium is affected by centrifugal force and friction and rises to a certain height along the cylinder wall, then falls freely, causing impact and crushing of the material; at the same time, the medium rolls and rubs at the bottom of the cylinder, achieving grinding and crushing through extrusion and shearing.