BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

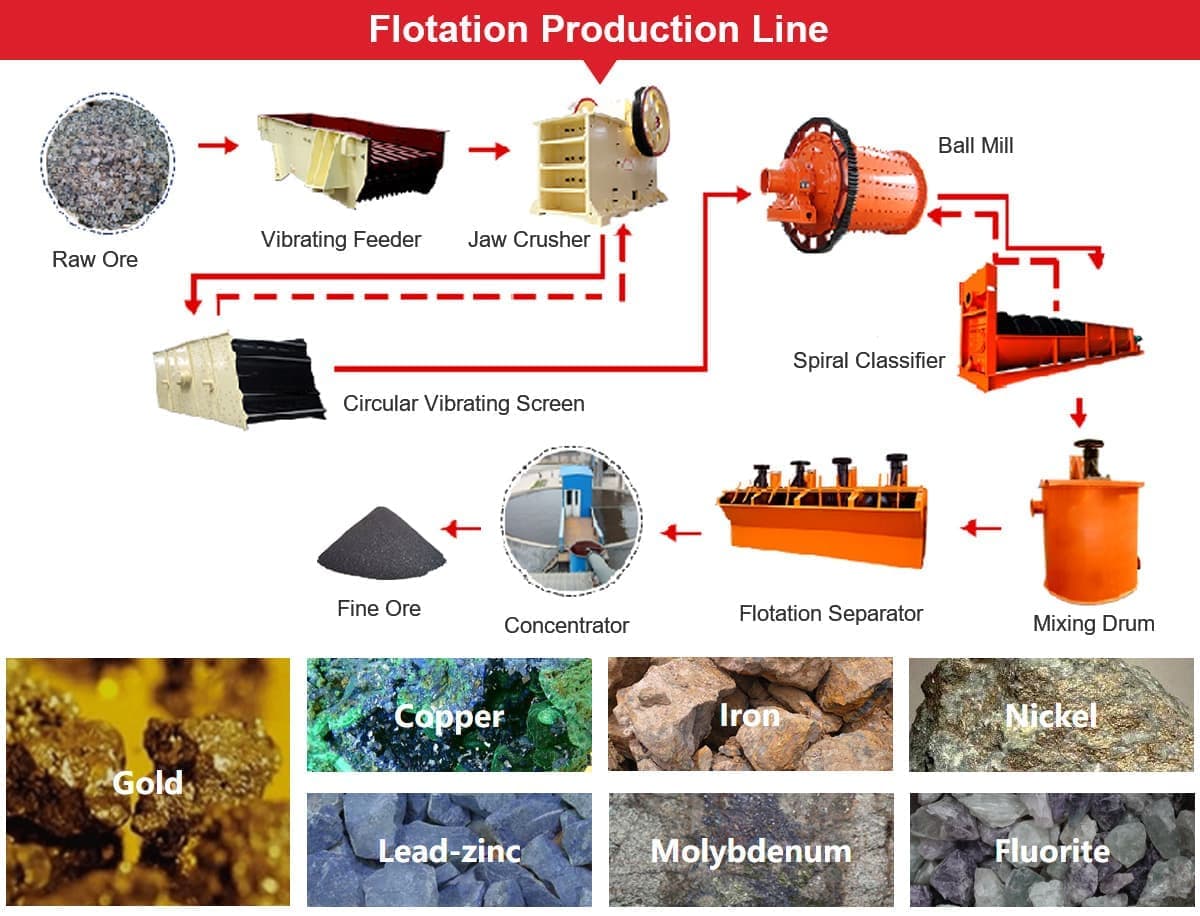

Flotation production line is a kind of separation technology commonly used in mineral beneficiation process, by injecting gas into the minerals and liquid and using the buoyancy and density difference of the flotation machine to separate minerals of different densities.ZOOMJO can develop a reasonable process flow according to the actual situation of users, which has the advantages of high production, low energy, high processing capacity and reasonable economy.

Flotation beneficiation is one of the important processes for application and is even more widely used. The flotation process can be clearly seen in the flotation flow chart designed according to the standard process. The flotation machine is an important device for flotation, and the pulp is fully aerated and agitated to enrich the useful minerals and complete the flotation operation. An important step in the process is the selection and operation of flotation chemicals so that good beneficiation can be achieved. Compared with other beneficiation methods, flotation beneficiation is economical and reasonable, and the results are very good.

Flotation is a beneficiation method based on the different wettability of minerals by water. Generally, the nature of the mineral easy to float and difficult to float is called the floatability of the mineral. Flotation is the use of the difference in the floatability of minerals to sort minerals. In the modern flotation process, the application of flotation chemicals is particularly important, because the flotation chemicals can change the floatability of minerals after treatment, so that the minerals to be floated can be selectively attached to the air bubbles, so as to achieve the purpose of mineral processing.

Flotation production line usually includes the following equipment: crusher, mill, mixing drum, flotation machine, defoamer, filter, centrifuge, dryer, conveyor and other equipment. Among them, flotation machine is the core equipment of flotation production line, its main function is to inject air or oxygen into the pulp to form bubbles and bring the bubbles to the mineral surface for separation, in order to achieve the purpose of flotation separation. Flotation production line is a special kind of mineral processing production line, which has technical advantages and wide application, and can effectively improve the utilization rate of ore and mineral sand, and bring more profit for mining enterprises.

Flotation production line is applicable to the separation of metallic and non-metallic minerals. Among them, metal minerals include gold, silver, lead, zinc, copper, molybdenum, nickel-iron, hematite, etc., and non-metallic minerals include feldspar, graphite, quartz, mica, feldspar, silica, etc. In mineral separation, flotation production line is widely used in various scenarios, such as mines, mineral processing plants, metallurgical plants, etc.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.