BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

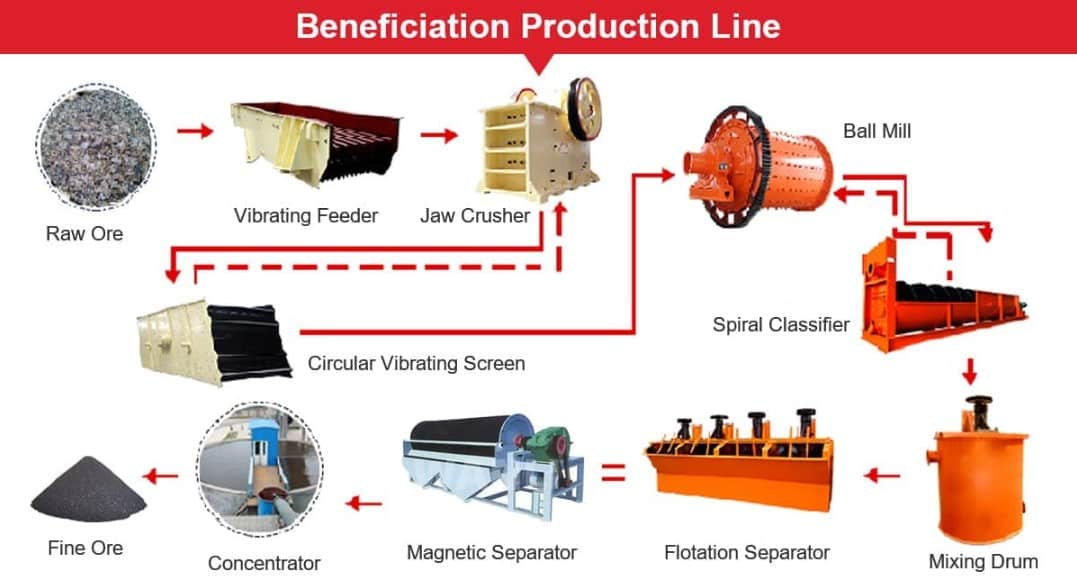

Mineral processing line is a kind of equipment used for mineral resources processing, which can process raw mineral materials into valuable minerals that can be used for commercial applications. The process flow of mineral processing line mainly includes crushing, sorting, grinding, flotation, washing, drying and selection.

The beneficiation production line is composed of main equipment such as jaw hammer crusher, cone crusher, ball mill, classifier, spiral classifier, magnetic separator, flotation machine, thickener and dryer, etc. Together with feeder, elevator and conveyor, it can form a complete beneficiation production line. This production line has the advantages of high efficiency, low energy, high processing capacity and reasonable economy.

The process flow of the beneficiation production line varies according to the nature of different ores and beneficiation index, but the basic process includes the following links.

Crushing: Crushing the raw ore for subsequent grinding and sorting operations.

Grinding: the crushed ore is finely ground for subsequent sorting and flotation operations.

Classification: classification of the ground ore by size for the subsequent flotation operation.

Flotation: the use of organic matter, frothers and other substances to float useful minerals on the water surface for separation purposes.

Re-selection: further separation of the ground ore by gravity, magnetism, electricity and other principles.

Commonly used mineral processing methods:

The re-election method is based on the difference of relative density of minerals to sort minerals. Mineral particles with different densities are subjected to hydrodynamic and various mechanical forces in the moving medium, resulting in suitable loose stratification and separation conditions, so that mineral particles of different densities are separated.

Flotation method is based on the difference of physical and chemical properties of mineral surface, treated by flotation chemicals, so that useful minerals selectively attached to the bubble, to achieve the purpose of separation. Non-ferrous metal ore beneficiation, such as copper, lead, zinc, sulfur, molybdenum and other ores are mainly treated by flotation; certain ferrous metals, rare metals and some non-metallic ores, such as graphite ore, apatite, etc. are also selected by flotation.

Magnetic separation method is based on the different magnetic properties of minerals, different minerals in the magnetic field of the magnetic separator by different forces, so as to get sorted. It is mainly used to sort ferrous metal ores (iron, manganese, chromium); it is also used to sort non-ferrous and rare metal ores.

The electric separation method is based on the difference in the electrical conductivity of minerals for sorting. When the minerals pass through the high voltage electric field of the electric separator, due to the different conductivity of the minerals, the electrostatic force acting on the minerals is different, and thus the minerals can be separated. Electric separation method is used for the separation of rare metals, non-ferrous metals and non-metallic ores. At present, it is mainly used for the separation and selection of mixed coarse concentrates; such as the separation of wolframite and cassiterite; the selection of zircon, the selection of tantalum-niobium ore, etc.

The beneficiation line is widely used in metal mines, non-metallic mines and coal mines, such as iron ore, copper ore, lead-zinc ore, gold ore, silver ore, phosphate ore, limestone, gypsum, quartz, etc. Meanwhile, it also has important applications in construction materials, chemical industry, metallurgy, environmental protection and other industries.

In order to improve the efficiency and product quality of the ore dressing production line, it needs to be optimized and improved. Among them, the common optimization measures include.

1. equipment upgrade: upgrading or replacing the equipment in the beneficiation production line to improve its production efficiency and product quality.

2. process improvement: improving the production efficiency and product quality of the beneficiation production line by optimizing the process flow.

3. Automatic control: Adopt modern automatic control system to realize the intelligent management of the beneficiation production line.

4. Energy saving and emission reduction: to achieve the goal of energy saving and emission reduction by optimizing the energy consumption and environmental issues such as waste gas and waste water discharge of the beneficiation production line.

5. Personnel training: strengthen the training and skills upgrading of the operators of the beneficiation production line to improve their operational skills and production awareness.

The design of mineral processing equipment production line is demanding and must take into account factors such as production environment, product quality and production efficiency, and combine with the actual situation of production to determine the best design plan.

ZOOMJO GROUP is a professional manufacturer of mineral processing equipment, providing products including lead-zinc ore beneficiation equipment, gold ore beneficiation equipment, hematite ore beneficiation equipment, copper ore beneficiation equipment, tungsten ore beneficiation equipment, manganese ore beneficiation equipment, limonite ore beneficiation equipment and so on. Our mineral processing equipment has been sold to Southeast Asia, Africa, America and other regions. Through optimization and improvement, we can greatly improve production efficiency and product quality to meet the needs of different industries and promote the sustainable development of the mining industry, which has won the praise of local customers.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.