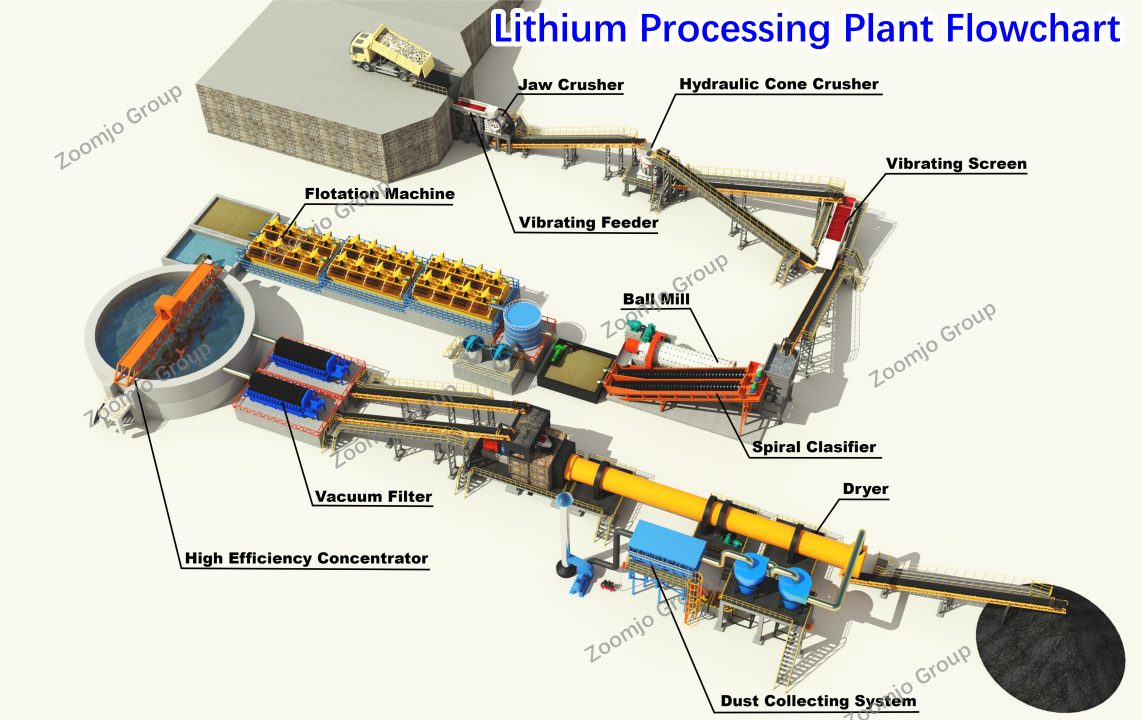

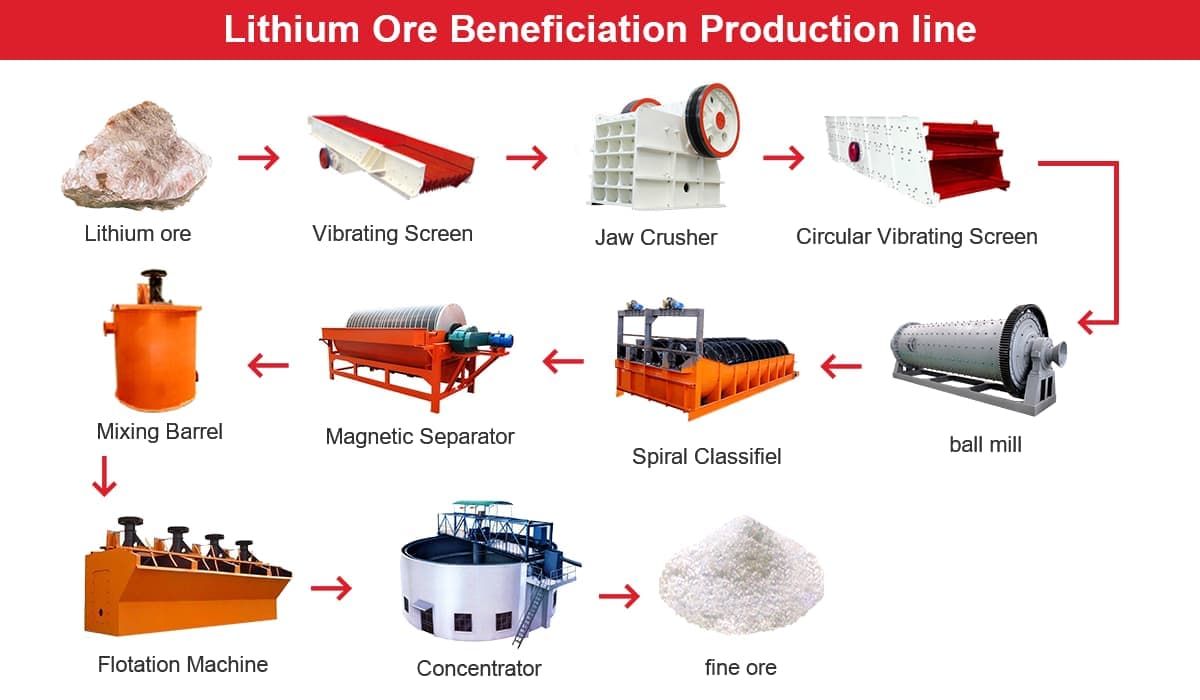

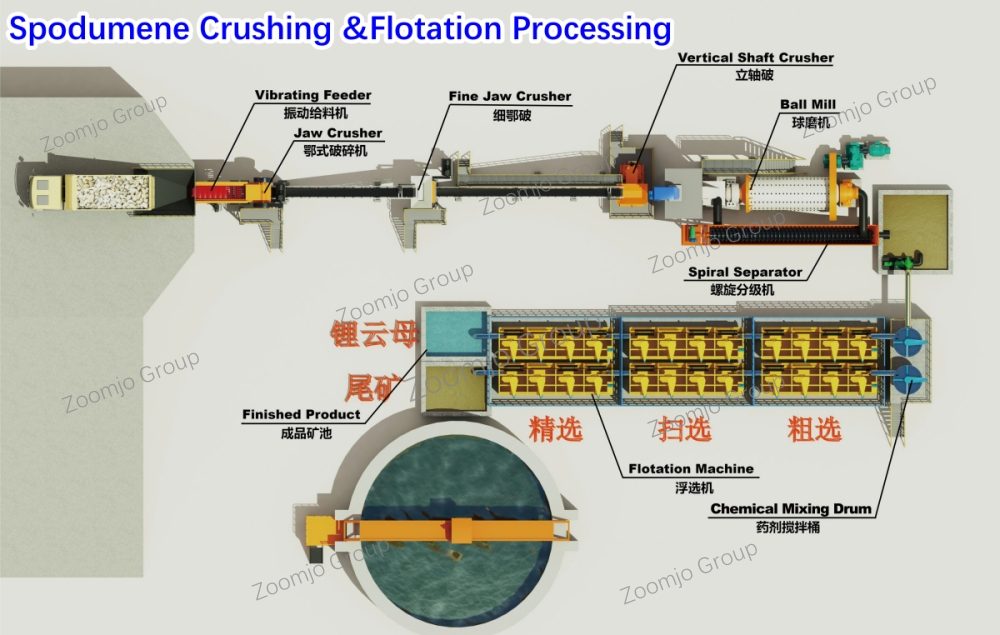

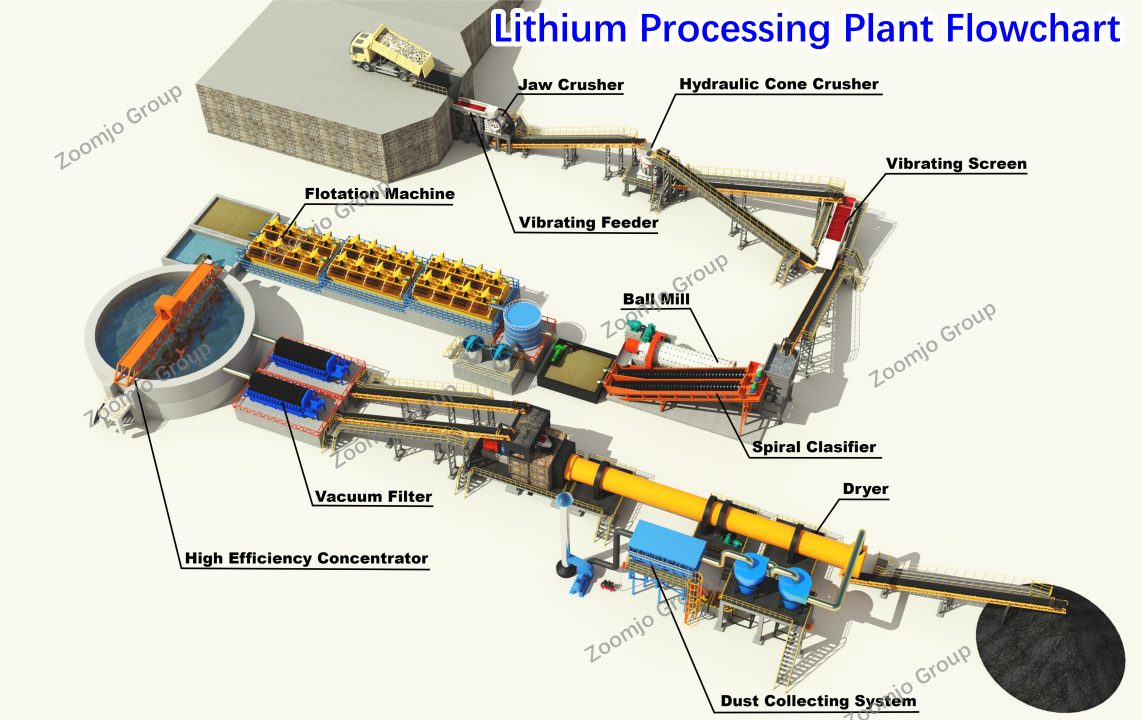

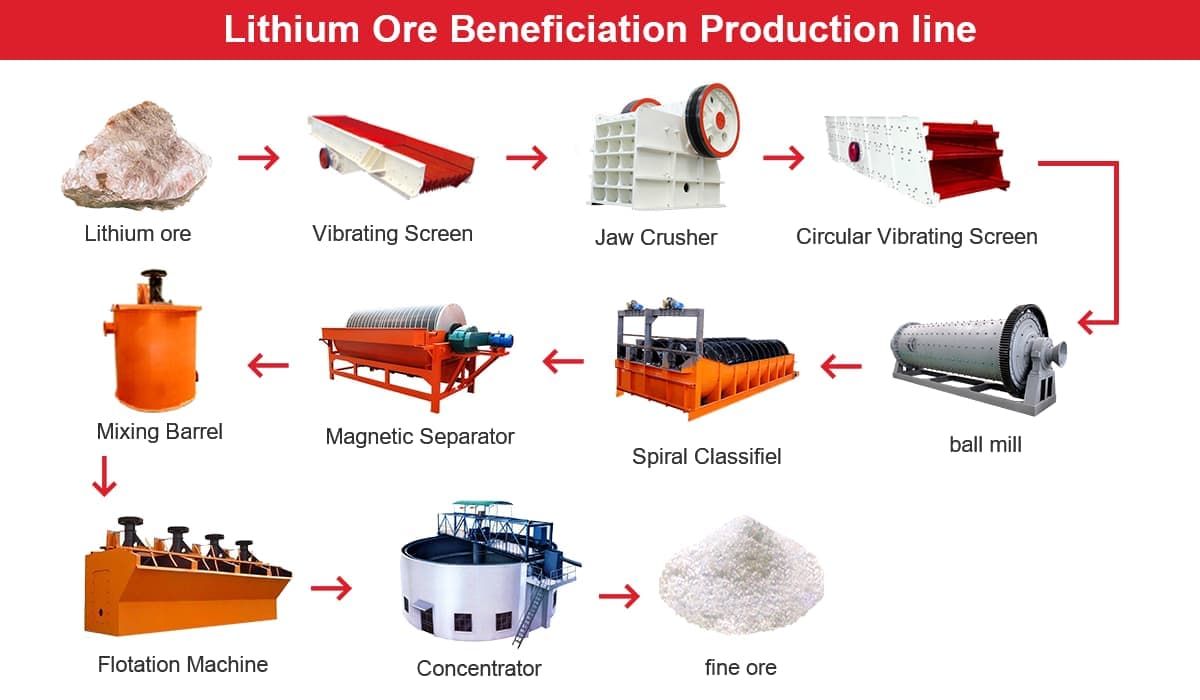

Building an efficient and complete lithium processing plant mainly includes crushing, grinding, beneficiation and some auxiliary equipment.

The most commonly used lithium processing plant equipment is crusher (jaw crusher, impact crusher, cone crusher), ball mill, spiral classifier, flotation machine, magnetic separator, thickener, dryer, etc.

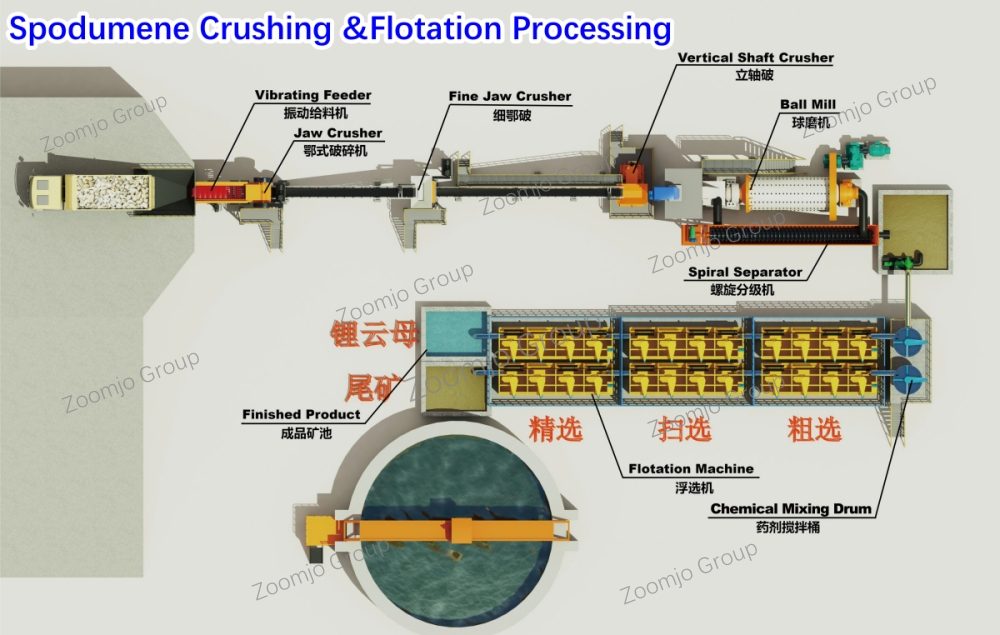

Lithium processing plant main process flow

1. Mineral testing as a first step

It is recommended to conduct a lithium mineral test before the separation and production.

Meanwhile, customers can customize the most effective and scientific beneficiation process and equipment based on the ore properties andinvestment budget to save costs.

2. Crushing + grinding process

Firstly, the lithium ore is crushed and grinded to obtain suitable particle size.

Crushing -The raw ore is first crushed by jaw crusher and cone crusher, which makes the particle size of crushed material < 20mm

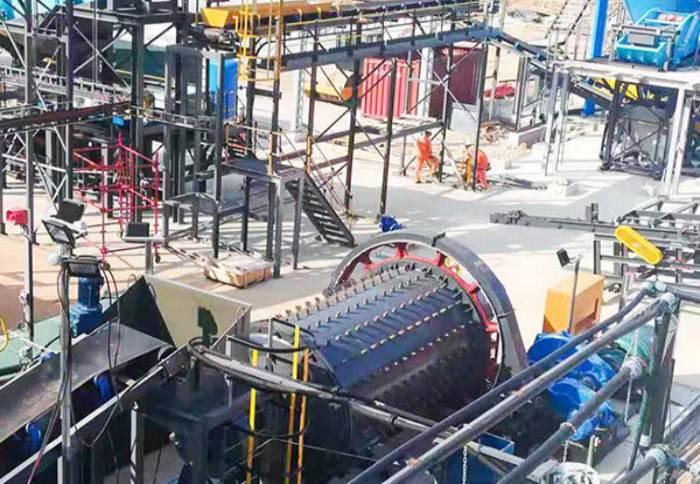

Grinding - using ball mill. Lithium ore particle size usually needs to be grinded to < 0.2mm for better flotation effect.

3. Beneficiation Process

In order to improve the grade of lithium ore, lithium beneficiation processing is required. Among them, flotation is the main method for producing lithium concentrate. Other methods such as magnetic separation, gravity separation and chemical methods play an auxiliary role.

Flotation separation

Flotation is currently the main method of separating lithium ores. Any lithium ore with industrial value can be concentrated by flotation.

Magnetic separation

Lithium ore is often associated with a complex composition, lithium concentrate obtained by flotation sometimes contains more iron, in order to improve the grade of lithium concentrate, the use of magnetic separation as an auxiliary method.

Get free lithium ore processing plant design flowsheet and investment cost now!

Zoomjo Group with 40 years of experience in mineral processing equipment manufacturer, can customise complete energy efficient and environmentally friendly mineral processing plant solutions and provide one-stop service, such as design, planning, installation, technical training and after-sales service. At present, we have established cooperation relationship with mines in more than 50 countries. If you are planning to build an mineral processing plant, Zoomjo Group looking forward to cooperating with you.