BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Magnetic separation production line is a new type of sorting equipment for coarse size ore sorting. Its working principle is to use the magnetic effect of magnetic substances to separate the materials, so as to achieve the sorting requirements of fine particle size ores. Magnetic separation equipment generally includes wet magnetic separator, dry magnetic separator and other types. Different types of equipment are suitable for different types of ores and production requirements. In addition, the magnetic field strength and magnetic media are also important factors affecting the magnetic separation effect.

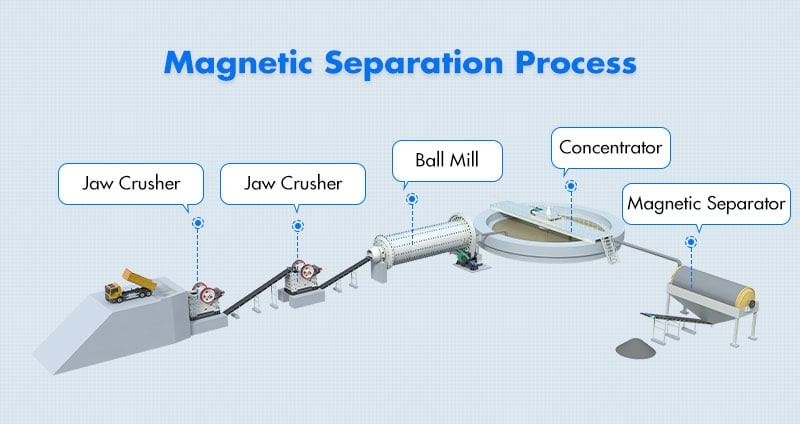

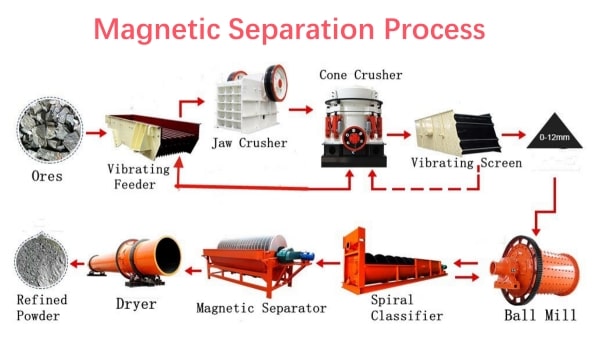

The mined ore is firstly crushed by the jaw crusher, and after crushing to a reasonable fineness, it is evenly sent to the ball mill through the elevator and feeder, and the ball mill crushes and grinds the ore. After the ball mill grinding, the ore fines enter the next process: classification. The spiral classifier washes and classifies the ore mixture by the principle that the specific gravity of solid particles is different and the speed of sedimentation in liquid is different.

When the washed and graded mineral mixture passes through the magnetic separator, the magnetic materials in the mixture are separated by magnetic and mechanical forces due to the different specific magnetization coefficients of various minerals. After the desired minerals are separated out, because they contain a lot of water, they must be concentrated by the initial concentration of the thickener, and then dried by the dryer to get the dry minerals.

The magnetic separation production line consists of vibrating feeder, trough feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, thickener and dryer and other main equipment, which can form a complete mineral processing production line with feeder, elevator and conveyor. This magnetic separation production line has the advantages of high efficiency, low energy, high processing capacity and reasonable economy.

The magnetic separation line is suitable for the separation and extraction of ores containing magnetic minerals. Its main application scenarios include but are not limited to.

Extraction of iron ore: Magnetic separation production line is a common process for extracting iron ore. In the magnetic separation process of iron ore, the magnetic materials (such as hematite and magnetite in iron ore) and non-magnetic materials (such as quartz and calcite) are separated out through the action of strong magnetic field, so as to obtain iron-containing concentrate, which is suitable for wet magnetic separation of magnetite, magnetic pyrite, roasted ore, ilmenite and other materials with particle size below 3mm.

Extraction of rare earth ore: Rare earth ore usually contains a variety of rare earth elements and its particle size is small. The magnetic separation production line can separate the useful elements in the rare earth ores through various process steps such as magnetic separation and flotation.

Extraction of tungsten ore, tin ore and other metal minerals: tungsten ore, tin ore and other minerals often contain a high proportion of magnetic minerals. The magnetic separation production line can separate these magnetic minerals to achieve the extraction of these metallic minerals.

1. The magnetic separation process is technologically advanced, the ore utilization rate can reach 90%, and the magnetic separation production line has high accuracy, which can accurately separate specific magnetic materials from non-magnetic materials.

2. The magnetic separation production line is highly productive and energy-saving, with advanced and good equipment combination, simple operation, low failure rate, low investment and high recovery rate.

3. The magnetic separation production line is equipped with advanced equipment, compact process, small footprint, low infrastructure investment and low operating cost of the magnetic separation production line, which can effectively reduce the production cost and improve the economic efficiency of the enterprise.

4. The maintenance of each equipment of magnetic separation production line is easy, and the wearing parts are made of wear-resistant materials, with small loss and long service life, which can save customers a lot of maintenance and repair costs.

ZOOMJO provides scientific and reasonable production line process design, including pre-sales, in-sales and after-sales services, and the magnetic separation production line has the advantages of simple process, perfect equipment, adjustable parameters, automatic control, wide application and technical innovation, which can effectively improve mineral separation efficiency and quality.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.