BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Copper ore processing plant is a high efficiency and low cost industrial production line for extracting high purity copper from raw copper ore. It can process various copper ore raw materials, including oxide copper ore, copper sulfide ore, mixed ore, etc.

According to statistics, more than 90% of copper-bearing minerals are treated using the flotation process. The flotation machine is an important device to carry out flotation. After the pulp is fully aerated and agitated, the useful minerals are enriched and the flotation operation is completed. An important step in the process is the selection and operation of flotation chemicals so that good beneficiation can be achieved. Compared with other beneficiation methods, flotation beneficiation is economical and reasonable, with better results.

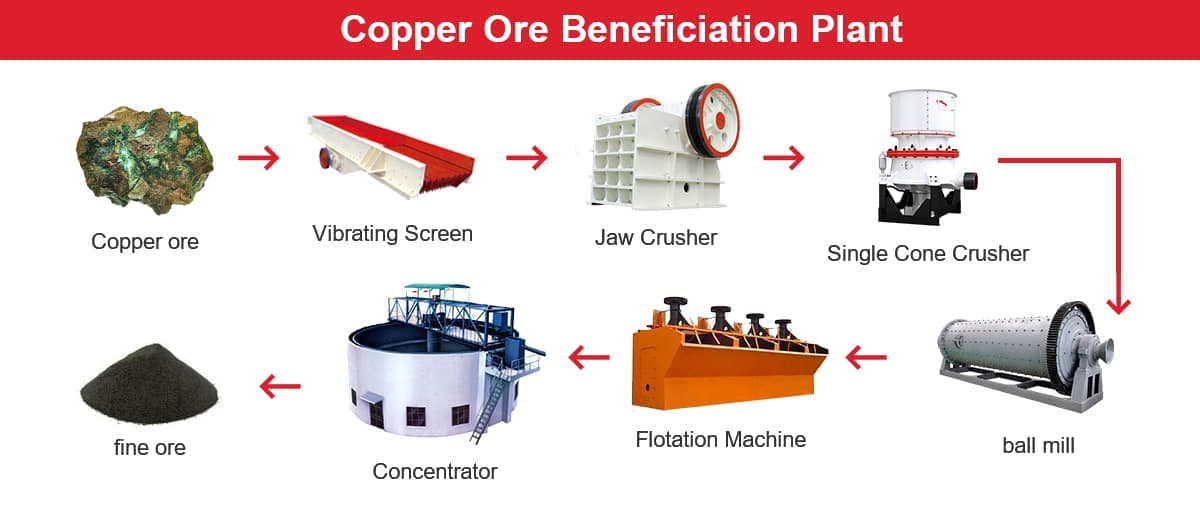

The production process of copper ore beneficiation line mainly includes several steps such as ore crushing, grinding, flotation, desliming, concentration and drying. Firstly, the raw material is crushed and ground finely, and then the copper ore is separated from the ore by flotation. Next, the copper ore is deslimed to make a higher concentration of copper, and is concentrated and dried to achieve the appropriate copper content.

The common equipment of copper ore beneficiation production line includes jaw crusher, cone crusher, ball mill, flotation machine, centrifuge, filter press, etc. In the production process, in order to ensure safety, various safety operation procedures and standards need to be strictly observed, such as fire prevention, explosion prevention and poison prevention.

Copper ore beneficiation production line is not only suitable for weak magnetic minerals beneficiation, such as hematite, brown iron ore, ilmenite, wolframite, tantalum-niobium ore, etc., but also can remove iron to purify non-metallic ores, such as should be time, feldspar, xythite, fluorite, silica line stone, lithium fai, kaolin, etc. In addition, the copper ore beneficiation production line developed by us can also be used for roughing and selecting copper, lead, zinc, aluminum, nickel, gold, silver and other non-ferrous metals and non-metals.

The advantage of copper ore beneficiation production line is that it can extract high purity copper from various copper ore raw materials, and at the same time can improve the recovery rate of copper. The production line also has the advantages of high production efficiency and low technical difficulty.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.