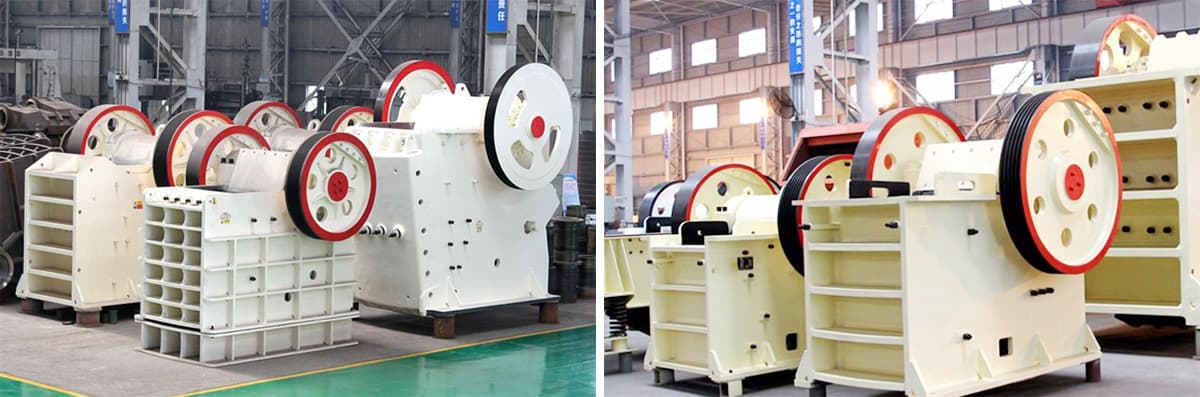

Jaw crusher is a very popular primary crushing equipment, mainly used in mining, quarrying and construction industries. It is chosen by customers for its high throughput, high crushing ratio, ease of maintenance and long service life.

Zoomjo jaw crushers have many types, widely used for crushing various stones and ores, such as granite, limestone, quartz, fluorite, basalt, pebble, pebbles, gold ore, copper ore, etc.

Hot selling models: PE250*400, PE400*600, PE600*900 ,etc. We also offer stationary and mobile jaw crusher, such as tyre-mounted mobile jaw crushers and crawler-mounted mobile jaw crushers. Depending on customers' requirements, jaw crushers are frequently combined with cone crushers, hammer crushers or impact crushers.

Jaw crushers with fuel-powered or electric drive options are available, with crusher models have small, medium and large scale. Discharge sizes can also be specified in various dimensions, such as 0-10mm, 10-20mm, 30-40mm, 60-80mm, G1, G2, 1/4’’, 3/4’’, etc., to meet the demands of different sites and customers.

The working principle of the jaw crusher is to put the material into the jaw crushing chamber of the crusher. In the crushing chamber, the material is clamped by the jaws and crushing plates, when the jaws rise, the material is crushed, and when the jaws fall, the material is crushed into smaller particle sizes, and finally the material at the crushing outlet is collected.

Model | Feed Opening Size (inch) | Feed Opening Size (mm) | Max. Feeding Size (mm) | Adjustable Range of Discharge Opening (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) | Overall Dimension (mm) |

PE250×400 | 10x16 | 250×400 | 200 | 20-50 | 5-20 | 15 | 2.9 | 1430×1310×1340 |

PE400×600 | 16x24 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 6.8 | 1700×1732×1653 |

PE500×750 | 20x30 | 500×750 | 425 | 50-100 | 40-100 | 45-55 | 11.2 | 2035×1921×2000 |

PE600×900 | 24x36 | 600×900 | 500 | 65-160 | 60-140 | 55-75 | 16.5 | 2290×2206×2370 |

PE750×1060 | 30x42 | 750×1060 | 630 | 80-150 | 90-230 | 90-110 | 29 | 2655×2302×3110 |

PE900×1200 | 36x48 | 900×1200 | 750 | 95-165 | 150-350 | 110-132 | 54.5 | 3789×3050×3025 |

PE1000×1200 | 46x48 | 1000×1200 | 850 | 105-185 | 180-400 | 132-160 | 56.5 | 3900×3320×3280 |

PE1200×1500 | 48x60 | 1200×1500 | 1020 | 150-300 | 400-800 | 220-250 | 99.6 | 4300×3540×4043 |

PEX150×250 | 6x10 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 0.85 | 896×745×935 |

PEX150×750 | 6x30 | 150×750 | 125 | 12-45 | 5-16 | 15 | 3.8 | 1205×1495×1203 |

PEX250×750 | 10x30 | 250×750 | 210 | 25-60 | 10-40 | 22-30 | 5 | 1667×1545×1020 |

PEX250×1000 | 10x40 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 6.8 | 1964×1550×1380 |

PEX250×1200 | 10x48 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 8.5 | 2192×1605×1415 |

PEX400×1200 | 16x48 | 400×1200 | 320 | 35-95 | 28-95 | 45-55 | 11.7 | 2256×2100×1960 |