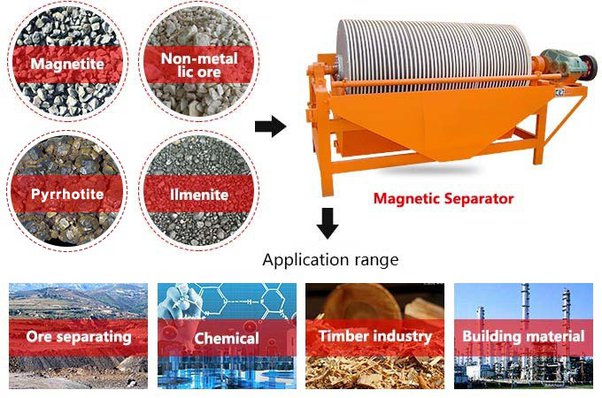

Magnetic separator, also known as magnetic separation equipment or magnetic separator, is an important equipment used in mining, steel, metallurgy, chemical, food and other industries. Its function is to separate materials according to magnetic differences, and it is commonly used to separate and recover materials such as ores, magnetic materials, steel scrap and iron scrap.

Magnetic separator is divided into many types, such as dry magnetic separator, wet magnetic separator, strong magnetic magnetic separator, high gradient magnetic separator, flat magnetic separator and so on. The advantages and disadvantages of different types of magnetic separators are different. For example, the advantage of the plate magnetic separator is that it can make the falling ore evenly distributed on the magnetic separator, which will not pile up into blocks and can better improve the precision of ore purification.

Magnetic separator has the characteristics of high separation efficiency, wide separation range, fast sorting speed, simple operation, safety and reliability, etc.. Its main application areas include mining, iron and steel, metallurgy, chemical industry, food and other industries, for example, in the mine, magnetic separator can be used to select magnetic ore, separating iron ore and non-magnetic ore, so as to improve the grade and recovery rate of iron ore; in the iron and steel industry, magnetic separator can be used to recycle and separate scrap steel, reduce the discharge of scrap steel and reduce environmental pollution; in the food industry, magnetic separator can be used to remove metal foreign matter in food, to ensure the quality and safety of food.

The magnetic separator is mainly composed of motor, reducer, magnetic roller, conveyor belt, slag discharge machine and electrical control system. When working, the materials are sent into the magnetic field of the magnetic roller through the conveyor belt. Due to the different magnetic properties of the materials, under the action of the magnetic field, the materials with less magnetic properties are subject to less force and are thrown away; while the materials with stronger magnetic properties are magnetically attracted and are transported to the other end along the direction of movement of the magnetic roller and are excluded by the slag releasing machine.