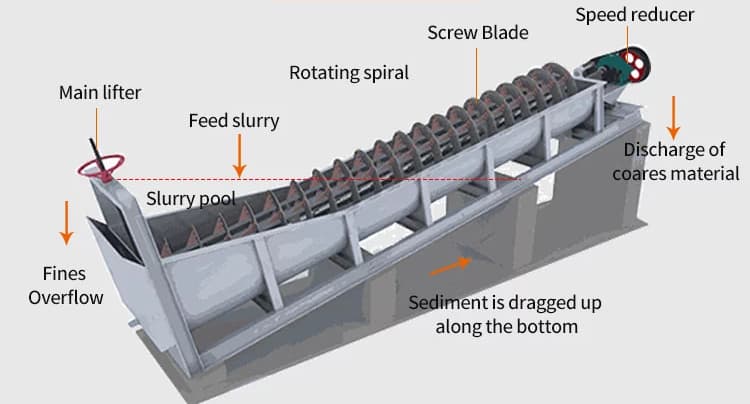

Spiral classifier is one of the equipment for mineral processing, spiral classifier is a kind of equipment for mechanical classification with the principle that the specific gravity of solid particles is different and thus the speed of settling in liquid is different. It can grade the material ground in the mill by filtration, then the coarse material is spun into the mill inlet by using the spiral piece spinner, and the filtered fine material is discharged from the overflow pipe.

Spiral classifier is referred to as classifier. The classifier mainly has four kinds of classifiers: high weir type single spiral and double spiral, sinking type single spiral and double spiral.

Spiral classifier is mainly composed of transmission device, spiral body, trough body, lifting mechanism, lower support (shaft tile) and discharge valve. Spiral classifier is widely used in mineral processing plant with ball mill to form a closed loop process to divert ore sand, or used in gravity separation plant to classify ore sand and fine mud, and metal beneficiation process to classify the size of the pulp, and ore washing operations such as de-mud, dewatering operations. It has the features of simple structure, reliable work and convenient operation.

The base of the spiral classifier is made of channel steel, while the body is made of welded steel plate, and the inlet head and shaft head of the spiral shaft are made of pig iron set, which is wear-resistant and durable and increases the service life of the equipment.

Spiral classifier is suitable for material range: gold ore, iron ore, copper ore, lead ore, molybdenum ore, zinc ore, aluminum ore, magnetic pyrite, hematite, limonite, coal, etc.

Spiral classifier is an important kind of equipment commonly used in mining, metallurgy, building materials and other industries, with the advantages of simple structure, convenient operation, easy maintenance, etc. It can effectively screen and classify minerals. However, it is also necessary to pay attention to the maintenance of the equipment and the cleanliness of water quality when using it to ensure the normal operation of the equipment and prolong the service life of the equipment.

Spiral classifier is based on the principle that solid particles are of different sizes and specific gravity, and thus have different settling speed in the liquid, with fine ore particles floating in the water into overflow and coarse ore particles sinking at the bottom of the tank. Pushed by the spiral to the upper discharge, to carry out mechanical classification of a classification equipment, can be ground in the mill material powder grade in the filter, and then the coarse material using the spiral piece of spinning into the mill inlet, the filtered fine material from the overflow pipe discharge.