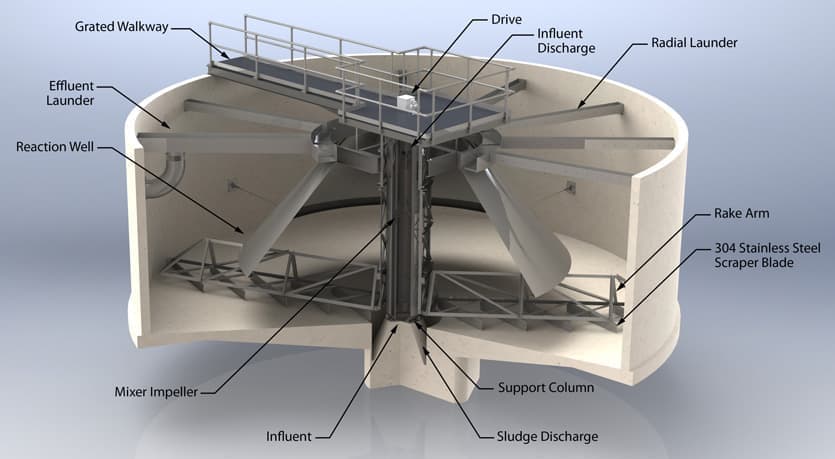

Thickener is an important continuous working thickening and clarifying equipment, mainly composed of two major parts: circular thickening tank and rake type mud scraper. In mineral processing plants, the thickener is usually used for concentrate concentration or tailings dewatering before filtration, and also for concentration and purification of solid-containing slurries in coal, chemical, building materials, and water and wastewater treatment industries.

The thickener is the core part of the thickener, in which the solid particles suspended in the slurry settle by gravity and the upper part becomes clarified water, so that the solid and liquid can be separated. The mud deposited at the bottom of the thickener is continuously scraped by the rake scraper and discharged to the bottom center of the pool, while the clarified water is overflowed from the top edge of the thickener.

In addition to the circular thickening pool and the rake scraper, the thickener also consists of several components, including the thickening pool, pozzolan, transmission device, pozzolan lifting device, feeding device, discharging device and signal safety device. The coordinated operation of these components enables the thickener to achieve efficient and stable operation.

1. adding flocculants to increase the particle size of settling solid particles, thereby accelerating the settling speed

2. installation of inclined plates to shorten the settling distance of mineral particles and increase the settling area

3. playing the role of flocculation, filtration, compression and increasing the treatment capacity of the thick phase layer of slurry deposition.

4. equipped with complete self-control facilities.

The traditional thickener works on the principle of gravitational settling of particles, and the settling speed is proportional to the square of particle diameter, which is inefficient when used to deal with microfine particles. In order to improve the sedimentation efficiency, the high efficiency thickener uses the reasonable use of flocculant and the bottom feeding fabric to improve the settling speed, which is one of the most important advances in concentration technology.

The problem of settling of fine-grained materials is the key to improve the settling efficiency of the thickener. The use of flocculants can solve this problem by causing the materials to collide with each other to form flocs and increase in volume, thus increasing the settling speed. In addition, the efficiency of the thickener can be further improved by installing inclined plates to shorten the settling distance of mineral particles and increase the settling area.