Dewatering screen is also called dewatering vibrating screen is one of the commonly used equipments in mining industry, which is used through crushing, screening, washing, tailings processing and so on, and is also called mine dewatering screen or tailings dewatering screen. Such as gold ore, copper ore, iron ore and other concentrates and tailings dewatering.

The main role of the dewatering screen is used for wet and dry grading of fine particle material dewatering, desliming, de-mediation, in addition to the mining industry can also be used for sand and gravel plant washing sand, coal plant coal sludge recovery ceramic mud dewatering, etc., and so also known as the sand and gravel dewatering screen, coal sludge dewatering screen, high-frequency dewatering screen, and so on.

Dewatering screen is often used to classify the crushed ore in the processing of metal ores (iron ore, copper ore) and non-metallic ores (quartz sand, limestone).

For example, in the iron ore processing plant, the slurry after crushing and grinding needs to be separated from the qualified coarse-grained materials (such as particles larger than 5mm) through the dewatering screen, and the fine-grained materials under the screen enter the subsequent magnetic separation or flotation process. At the same time, the dewatering screen can dewater the ore after washing, reduce the water content of the material, and facilitate the transport and subsequent smelting.

Case: A copper ore processing plant in South Africa adopts double-deck dewatering screen to classify copper ore, the aperture of the upper screen is 10mm, and the lower screen is 3mm, which realises efficient separation of coarse, medium and fine grains, and the screening efficiency is 15% higher than that of traditional equipment.

Tailings Dry Drainage Processing

With the improvement of environmental protection requirements, tailings dry drainage has become a mainstream trend in the mining industry. Dewatering screen combined with filter press, cyclone and other equipment can reduce the water content of tailings slurry from 30%-50% to 15%-20%, forming a dry heap state, which can reduce the floor space and environmental pollution.

For example, in the processing of gold mine tailings, the dewatering screen carries out preliminary dewatering of tailings slurry, the dry slag on the screen is directly transported to the tailings storage, and the waste water under the screen is recycled after precipitation, which realises the efficient use of water resources.

Coal Washing and Processing

In the coal industry, dewatering screen is used for dewatering and classification of concentrate coal, medium coal and gangue. For example, in the coking coal washing process, the dewatering screen can reduce the moisture content of fine coal from 25% to less than 12%, which can satisfy the strict requirements of coking process on the moisture content of raw materials, and at the same time, reduce the loss of coal transport and environmental pollution.

Dewatering screen is also often combined with sand washer, cyclone and other equipment to form an integrated fine sand recovery machine, washing, grading, dewatering of materials, etc., one machine multi-purpose, easy to operate, low investment costs, high quality of the finished sand and high fine sand recovery rate.

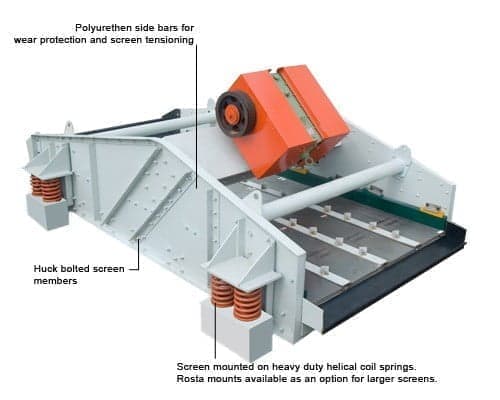

Dewatering screen is to use the vibration effect of the screen mesh to screen out the water and impurities in the material, so as to achieve the purpose of dewatering, desliming and grading. Dewatering screen usually consists of screen box, vibrator, screen mesh, damping spring and other parts. When the dewatering screen starts, the vibrator will drive the screen mesh to do high-frequency vibration, the material on the screen mesh is subjected to vibration and gravity, the moisture and impurities will be discharged through the screen mesh, and the screened material will be discharged from the screen mesh outlet.