Background: The chromite ore in South Africa has chromium oxide content is 35.25 % and ferrous oxide content is 9.55%, and which main veinstone minerals include olivine, serpentine and chlorite.

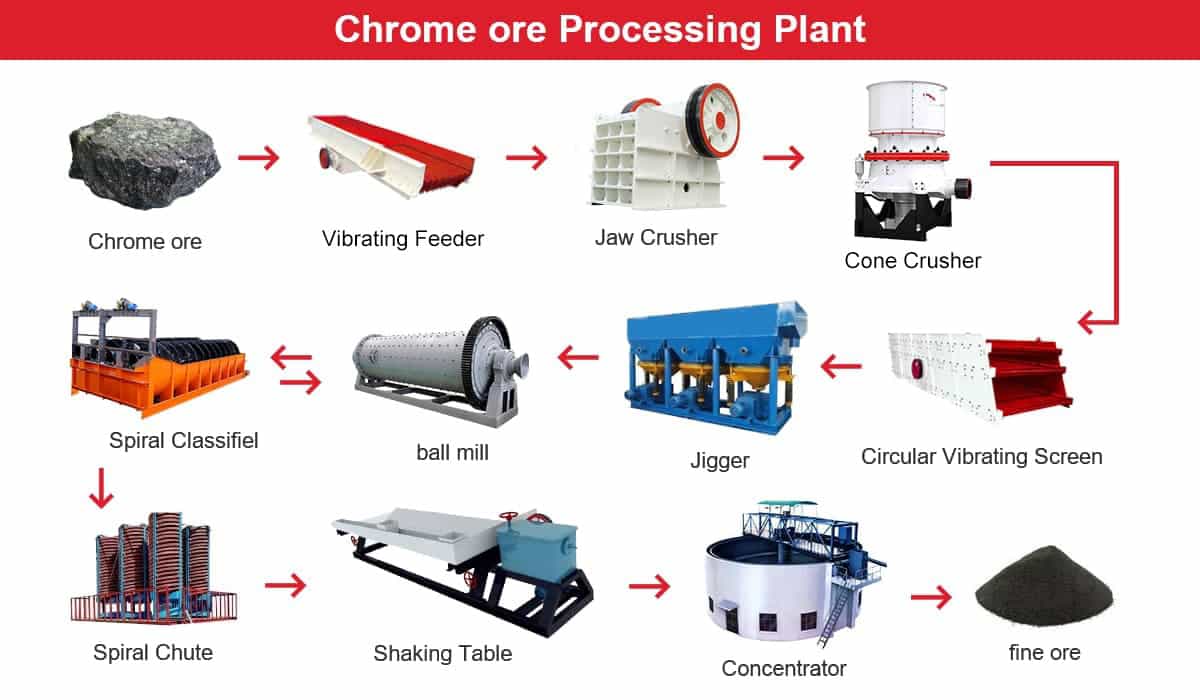

Chromite ore beneficiation process flow:

1,Crushing

Chromite first through the jaw crusher for coarse crushing, and then into the vibrating screen for screening, after screening the material ≥25mm into the fine jaw crusher or cone crusher for secondary crushing, ≤25mm material directly into the ball mill for grinding.

2, Grinding

Chrome ore through the feeder, belt conveyor into the ball mill grinding, grinding material particle size of 0.074-2mm into the re-selection, unqualified materials return to continue grinding

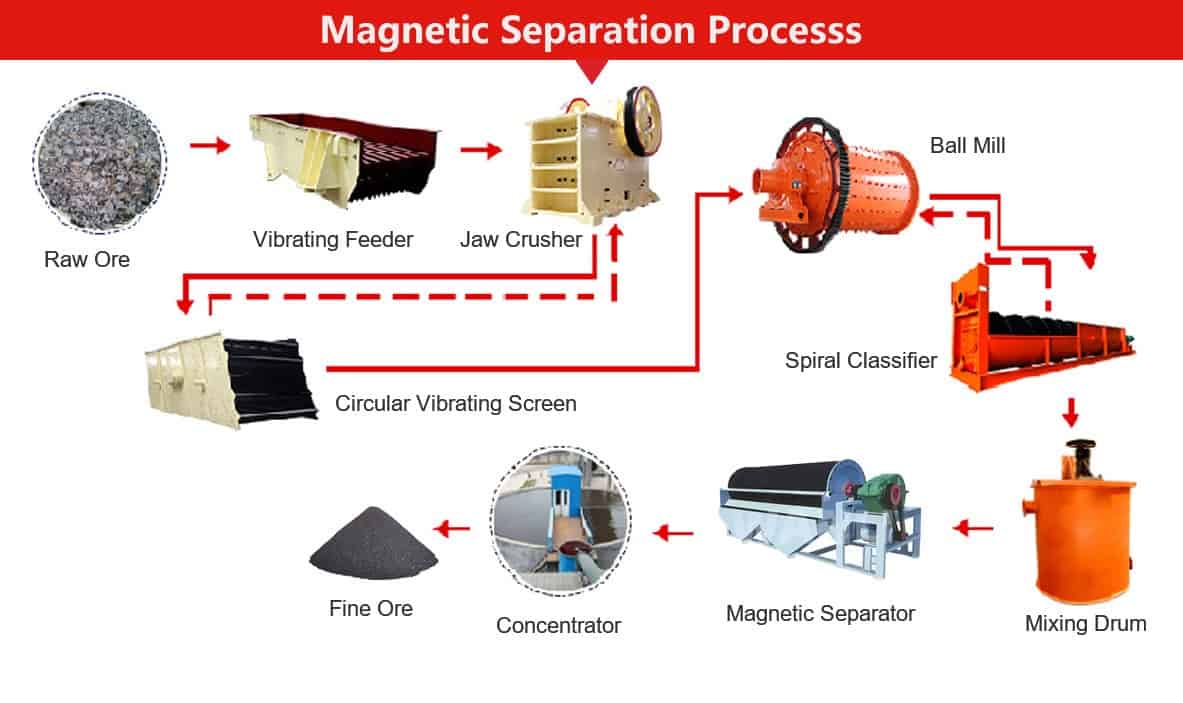

3, Magnetic separation, gravity separation

Mainly use magnetic separator and shaking table equipment to select chromite ore and improve the recovery rate of tailings. The grade of chromium oxide concentrate is 47.61%, and the recovery rate is 96.26%.

Customer Feedback

The chrome ore beneficiation solution designed by Zoomjo is very suitable for our current needs, the whole beneficiation production line from design, construction to operation in less than 8 months, and the investment cost is low, and the rate of return is high. The chromite processing plant has stable performance, small footprint, simple operation, high recovery rate and high enrichment ratio.

Shaking Table

Shaking Table

Spiral classifier

Spiral classifier

Magnetic Separator

Magnetic Separator