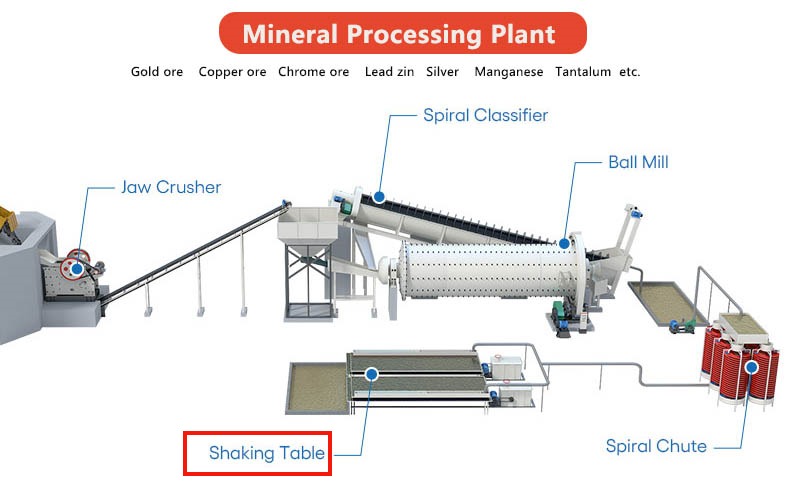

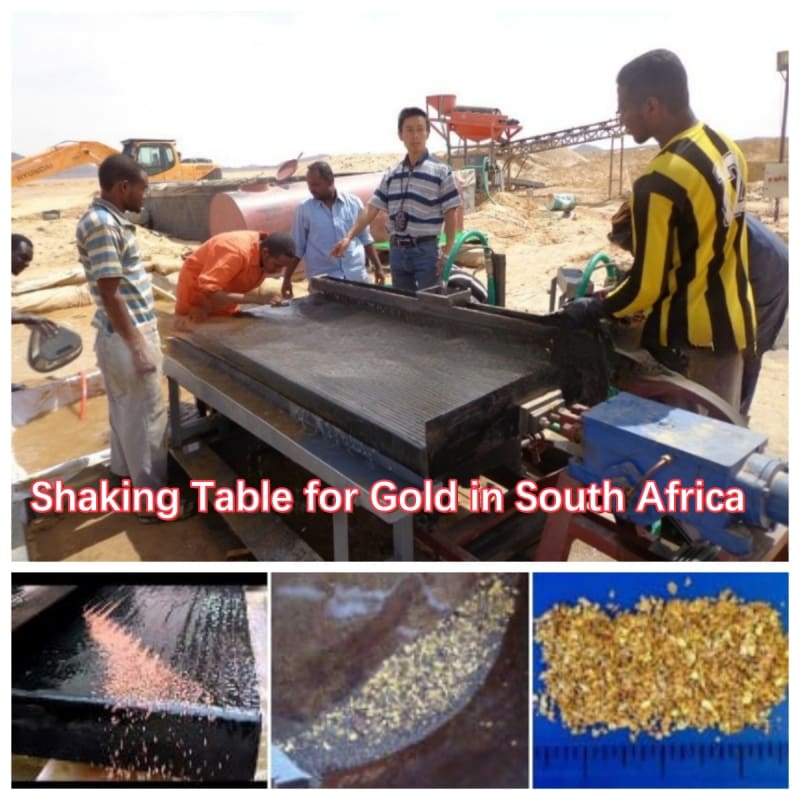

Shaking table in mineral processing plant

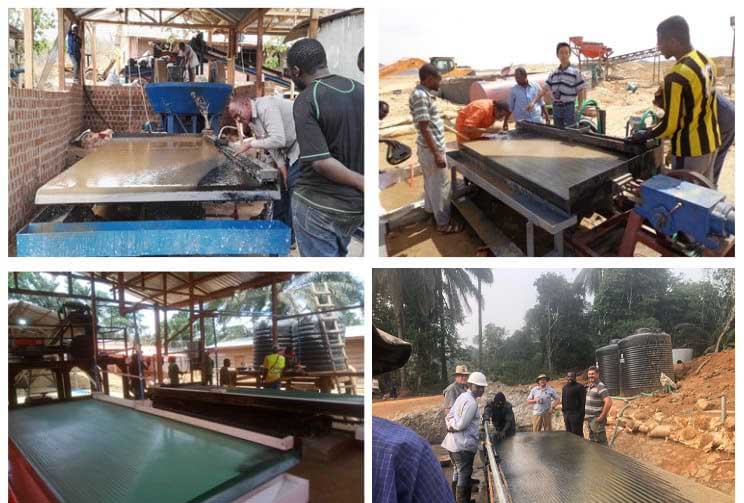

In the mineral processing plant, shaking table is usually used for the gravity separation and concentration process of minerals containing gold, iron, copper, tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, titanium, etc.

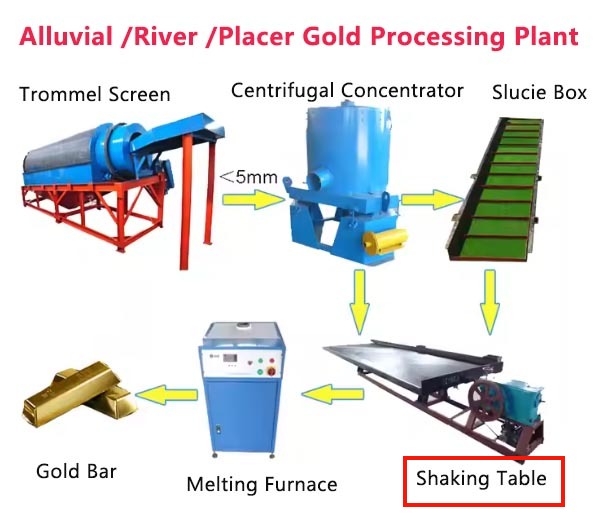

Shaking table mineral processing can not only be used as a single beneficiation method, but it is often used in combination with jigging, flotation, magnetic separation, and centrifugal concentrators, spiral concentrators, sluice boxes, belt chutes, and other beneficiation equipment.

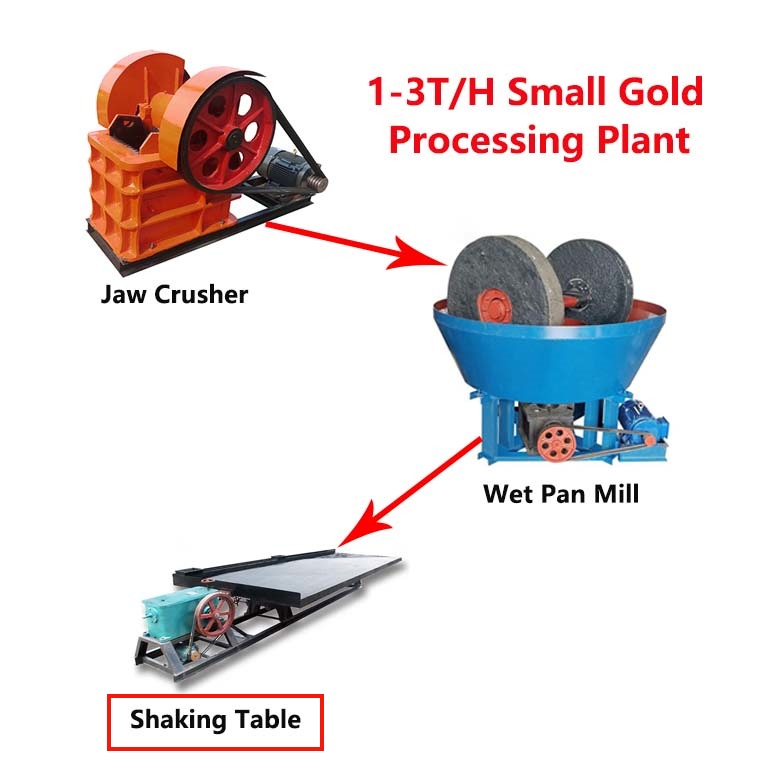

Shaking table with simple operation, concentration ratio, excellent separation efficiency, long working life, low investment cost. It is very popular in gold ore separation plant and which is the best equipment for extracting gold from gold sand, alluvial gold, placer gold.

The ange of article ize of shaking table for separating ores

Metal ores: 3-0.02mm

Ores: ≥0.5mm

Fine sand: 0.5-0.74mm

Sludge: 0.074-0.074mm

The effective range of particle size of shaking table is 3-0.02mm, and shaking table is a very effective separating equipment for separating fine-grained materials under 1mm, especially under 0.1mm.

Cost effective shaking table for you

Zoomjo factory direct sale, low price for sale, various types of shaking table for sale, widely used in gold ore, copper ore, iron ore, lead zinc, etc. Low investment cost and fast return. Contact us for the latest shaking table equipment price.

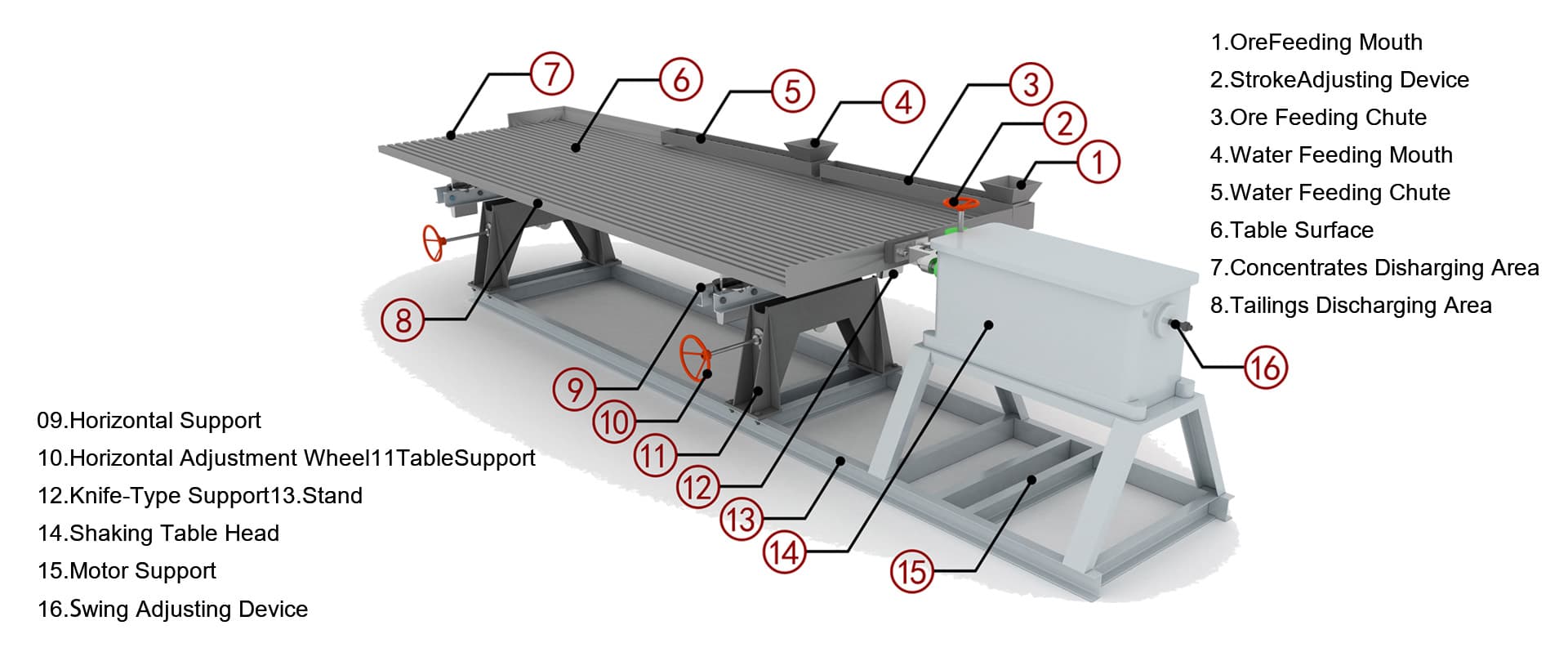

The working principle of the shaking table is to apply horizontal vibration force to the shaking table so that the mineral particles move back and forth continuously on the shaking table. During the movement, the mineral particles with larger specific gravity will sink into the groove of the trough plate, while the mineral particles with smaller specific gravity will flow into the chute, thereby realizing the separation of minerals.