Gold centrifugal concentrator commonly referred to as the Knelson concentrator, mineral concentrator centrifuge, gold separator machine, centrifugal gold concentrator, gold recovery centrifugal or gold concentrator machine, etc.

Gold centrifugal concentrators are suitable for the recovery of precious metals, including silver, gold, chromite, platinum, tungsten and other metals, which are more widely used in the enrichment and recovery of alluvial gold, vein gold and other non-ferrous metals associated with gold.

Gold centrifugal concentrator is one of the gravity separation equipment, due to the large processing capacity, wide range of separation size, simple operation and maintenance, as a roughing or sorting is used in the separation of gold, tin, tungsten, titanium, hematite and so on. It can also be used for recovering gold ore, and other metals in the monomer gold, the separation of vein gold ore in the monomer gold is extremely effective, can replace the mercury plate.

Features

1, High concentration ratio, usually up to 1000-3000 times, concentrate yield is small, usually 0.02%-0.10%, concentrate grade is high, usually 1000-20000g/t, recovery rate is significantly higher than conventional gravity separation equipment.

2, A single equipment to deal with a large amount of solid ore, processing capacity can reach 100-1000t / h respectively.

3, Environmentally friendly (no chemical additives or reagents).

4, The equipment has high operating rate, low power consumption, easy operation and management, few operators required, high automation and low production cost.

5, Compact design, small footprint, easy integration into existing mining processes.

6, The selection process short, low investment, short return time, usually 1 month to 1 year.

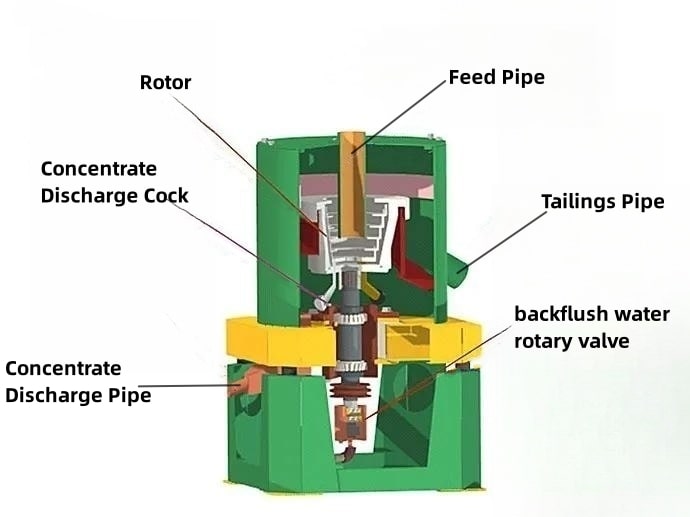

Mineral concentrator centrifuge is a new type of gravity separation equipment. Centrifugal concentrator operation, the motor drives the drum rotating at high speed, the slurry with the drum to do high-speed rotation, in the strong centrifugal force, heavy minerals will be deposited on the inner wall of the drum, light minerals will be discharged through the tailings chute. After 3 minutes of sorting, the ore feed separator automatically goes to the position of concentrate discharge and stops running, after the concentrate is discharged, the ore discharge separator and ore feed separator automatically reset to start the next sorting cycle.

| Model | STLB20 | STLB30 | STLB60 | STLB80 | STLB100 |

| Capacity (T/H) | 0-0.60 | 2-3 | 10-15 | 35-40 | 80-120 |

| Feed Particle Size(mm) | 0-3 | 0-4 | 0-6 | 0-6 | 0-6 |

| Feed Concentration(%) | 0-50 | 0-50 | 0-50 | 0-50 | 0-50 |

| Backwash Water Volume (T/H) | 1.5-2 | 4-6 | 10-15 | 17-25 | 40-60 |

| Concentrate cleaning cycle | 岩金矿每1-3 小时 砂金矿每2-6 小时 | ||||

| Concentrate Capacity( kg/次) | 2-3 | 10-20 | 30-40 | 60-70 | 70-80 |

| Motor Power(kw) | 0.75 | 1.5 | 7.5 | 15 | 18.5 |

| Rotation Speed | 800 | 600 | 460 | 400 | 360 |

| Water Pressure(MPa) | 0.04 | 0.1 | 0.16, | 0.18 | 0.2 |

| External Dimensions(mm) | 790x785x790 | 1180x1140x1250 | 1970x1670x1750 | 23,00x1800x2200 | 2500x2200x2400 |

| Weight(kg) | 145 | 400 | 1300 | 1500 | 2000 |