BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Feldspar is a common mineral, mainly used in the manufacture of ceramics, glass, building materials, rubber, paint and other products. Feldspar beneficiation production line is the production line to separate and purify feldspar from the raw ore.

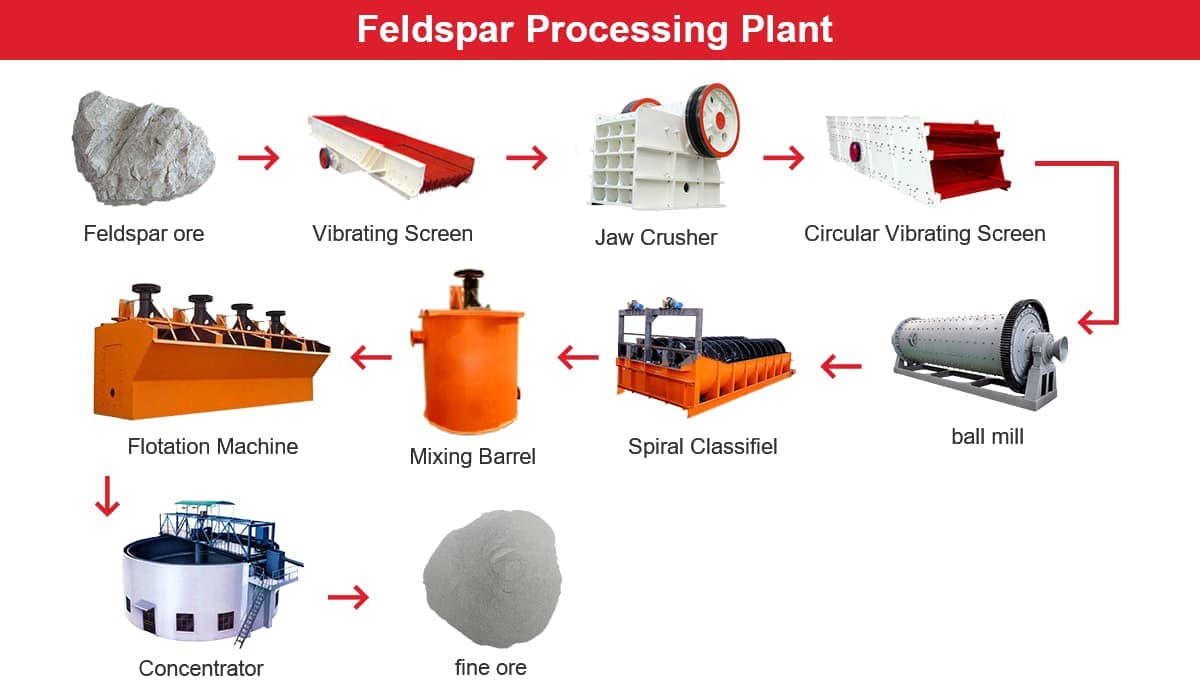

The process flow of feldspar beneficiation production line includes crushing, screening, grinding, magnetic separation and other steps. First, the raw feldspar ore is coarsely crushed by the crusher, then screened by the sifter to remove impurities and unwanted particles. Next, the feldspar ore is fed to the mill for fine crushing to improve its purity and availability. Finally, the feldspar ore is subjected to magnetic separation to remove impurities and other metallic elements. The feldspar beneficiation production line has the features of high efficiency, low energy, high processing capacity and reasonable economy.

Feldspar beneficiation equipment mainly includes jaw crusher, ball mill, spiral chute, shaking bed, iron removal magnetic separator, flotation machine to mica equipment, etc., with the feeder, bucket elevator, tape transfer can form a complete beneficiation production line. Crusher is mainly used to coarse crush the raw feldspar ore, sifter is used to remove unwanted particles, mill is used for fine crushing treatment, magnetic separator is used to remove impurities and other metal elements.

Feldspar is a mineral with high hardness, high abrasion resistance, high chemical stability and other characteristics. The feldspar products produced by the feldspar beneficiation line usually have high purity and uniform particle size and are suitable for many fields such as ceramics, glass, building materials, rubber, coatings, etc. Feldspar is used in a wide range of application scenarios, such as for the manufacture of ceramic porcelain, glassware, building materials, artificial stone, cosmetics, rubber, etc.

Feldspar beneficiation production line has the advantages of high automation, simple operation and high efficiency, which can effectively improve the production efficiency of feldspar beneficiation and meet the needs of large-scale production.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.