BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Graphite is an important non-metallic mineral, which can be used in casting, coating, battery, high strength material and other industries. Graphite beneficiation production line is widely used in the development and utilization of graphite ore resources.

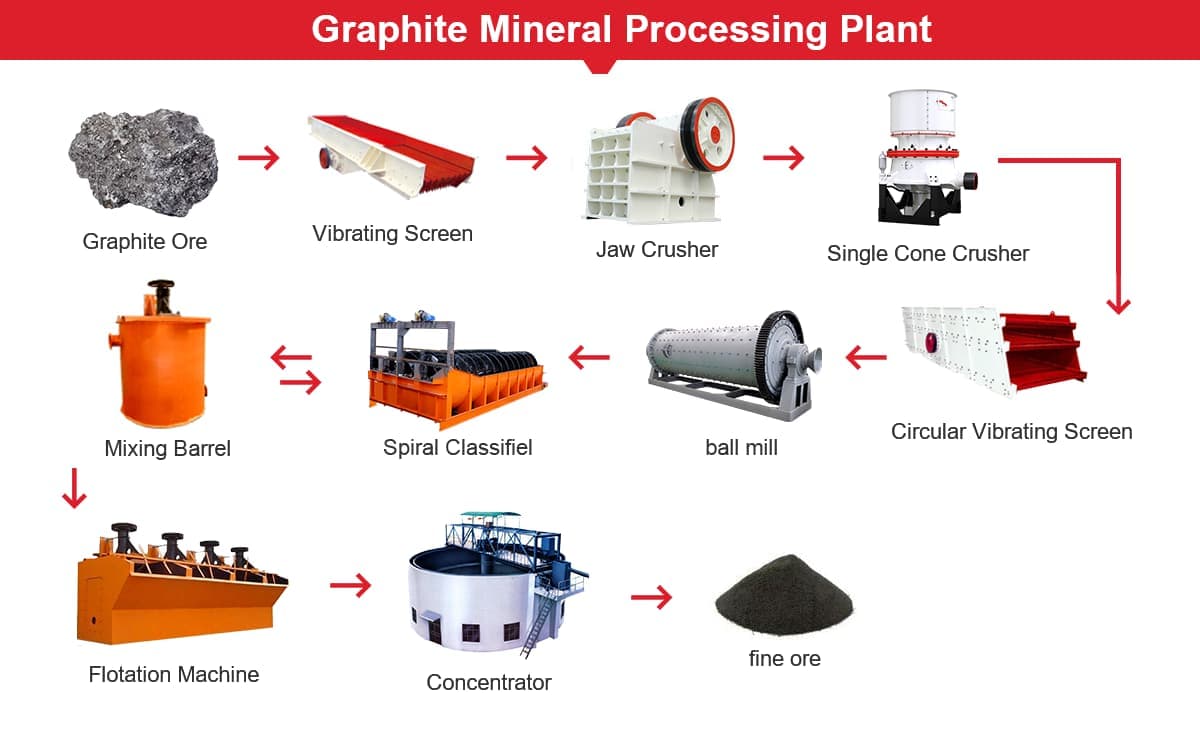

Graphite ore can reduce graphite crystallinity and improve flotation effect after pretreatment such as crushing and grinding. Generally, jaw crusher, cone crusher, ball mill and other equipment are used for processing.

The main components of graphite ore are graphite and impurity minerals, and flotation is the key process of graphite beneficiation production line. Through graphite ore flotation, graphite and impurity minerals can be separated to improve the grade and recovery rate of graphite. Graphite ore flotation mainly uses mechanical flotation method and chemical flotation method. The mechanical flotation method uses flotation machines, mechanical agitation flotation machines and other equipment, while the chemical flotation method uses chemicals to treat the graphite ore in order to change the surface properties of graphite and impurity minerals, and then achieve separation.

After flotation, the graphite ore concentrate needs further treatment to remove impurities and improve the grade of graphite. Graphite ore concentrate treatment mainly adopts the processes of sorting, drying and sintering. Among them, the common sorting equipment include vibrating screen, rotary screen, spiral sorter, etc.

The tailings produced by the graphite ore beneficiation production line contain a certain amount of graphite and impurity minerals. In order to achieve the environmental protection requirements and resource recovery, it is very necessary to treat the graphite mine tailings. Graphite mine tailings treatment generally uses tailings leaching, oxidation roasting, membrane filtration and other processes. These treatment methods can reduce the impact of tailings on the environment.

Graphite ore dressing production line can effectively improve production efficiency, reduce production cost, improve product quality and provide users with higher quality graphite products. It greatly improves the recycling of graphite and meets the needs of different industries for graphite processing.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.