BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Nickel is an important metal element, which is widely used in steel, chemical industry, new energy and other fields. Nickel ore is the main source of nickel, and the beneficiation line of nickel ore is able to remove the impurities from nickel ore to get higher purity nickel ore. Nickel ore is mainly divided into copper-nickel sulfide ore and nickel oxide ore, and the beneficiation and processing methods of the two are completely different. Copper-nickel ore is mainly used for flotation, while nickel oxide ore can only be smelted directly at present.

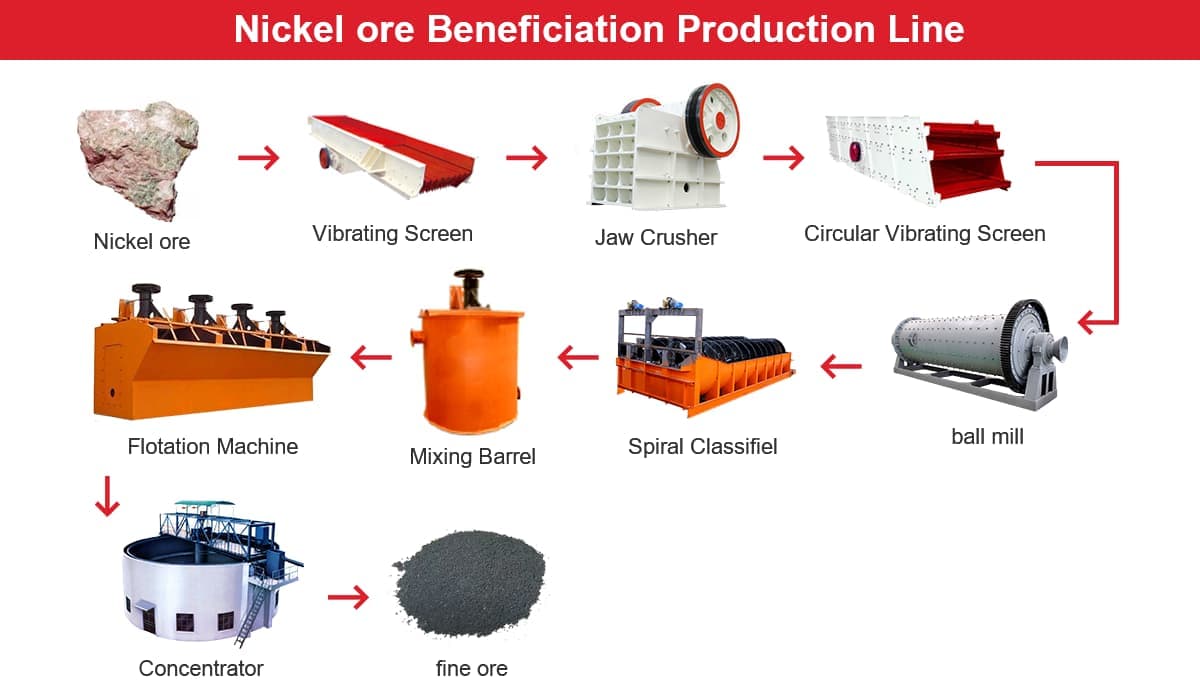

Nickel ore beneficiation production line mainly carries out the process of crushing, screening, flotation, magnetic separation, re-election and dewatering on the raw ore by physical and chemical methods, so as to separate the ore with higher nickel content and improve the extraction efficiency and product quality. In the whole beneficiation process, the equipment of each link plays a vital role, so it is important to choose the right equipment to improve the beneficiation efficiency and product quality.

In the beneficiation production line, crushing equipment, grinding equipment, flotation equipment, magnetic separation equipment, re-election equipment and dewatering equipment are all essential equipment.

In the crushing and grinding step, nickel ore is crushed into small pieces and then ground finely by ball mill or other grinding equipment. In this step, water is added to the nickel ore to form a slurry that facilitates the subsequent flotation process. In the flotation step, the pulpy material is injected into the flotation machine, and after the action of the air bubbles, the nickel ore particles are adsorbed in the air bubbles to rise to the liquid surface, thus achieving the separation and extraction of the metallic nickel.

In the dewatering and drying step, the nickel ore slurry obtained from the flotation machine is filtered and dewatered, and then dried in a rotary dryer to obtain nickel in concentrate. The nickel ore beneficiation line can be applied to copper-nickel ore or nickel oxide ore accompanied by pyrite and various other veinlets.

The operation of the entire nickel ore beneficiation line requires a high degree of technical and operational knowledge, as well as the use of advanced equipment and technology to ensure the extraction of high purity nickel metal. Typically, this production line is highly automated to reduce labor costs and increase production efficiency, while also saving energy and water resources and reducing the environmental impact.

The key to the beneficiation production line is the quality of the equipment and the optimization of the process. ZOOMJO, as a professional nickel ore beneficiation production line manufacturer, is able to provide customized beneficiation production lines to meet the different needs of customers, and also provide excellent after-sales service to provide a full range of protection for customers' production.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.