BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Phosphate ores are mostly produced in sedimentary rocks, but also in metamorphic and igneous rocks. Phosphorus in minerals always exists in the form of orthophosphate, and the main mineral of phosphorus is apatite. Phosphorus is an important chemical material and an essential element for the growth of crops. Industrial phosphorus must be extracted in large quantities from phosphate ores for the manufacture of yellow phosphorus, red phosphorus, phosphoric acid, phosphate fertilizer and phosphates. Phosphate ore has important uses in agriculture, medicine, matches, dyes, sugar, food, textiles, glass and ceramics.

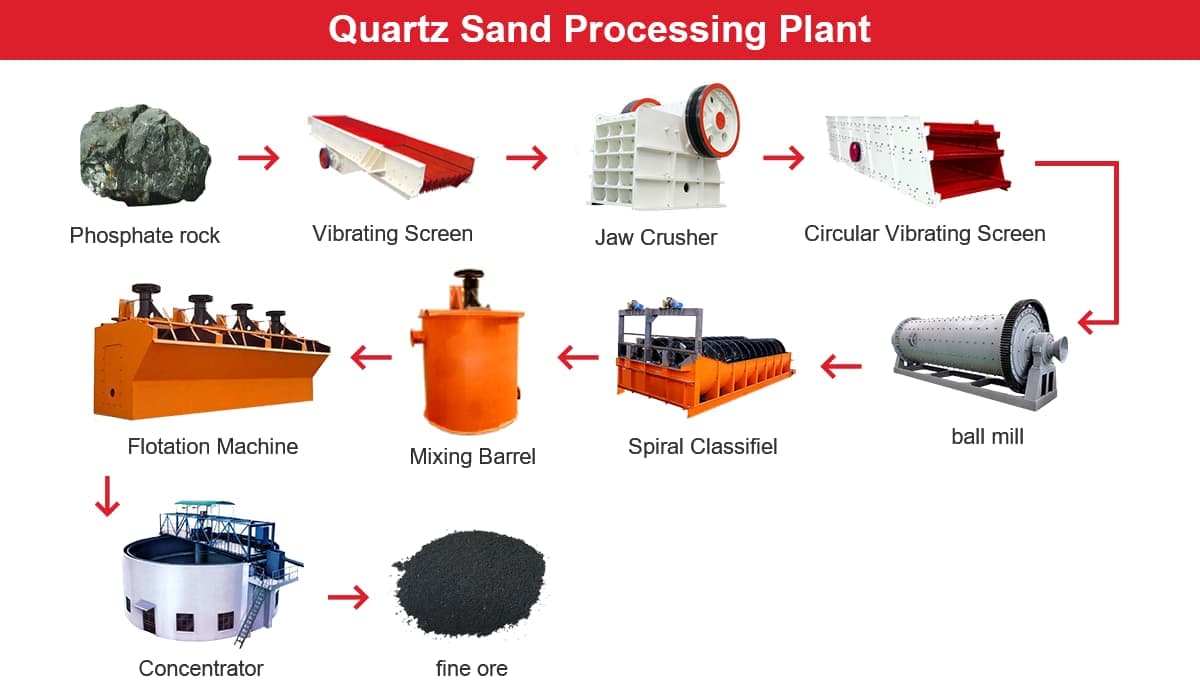

The process of phosphate ore production line mainly includes crushing, grinding, leaching, precipitation, filtration, drying and other parts. Among them, leaching process is the key step of the whole production line, which dissolves phosphate from the ore through chemical reaction, and then removes impurities through precipitation and filtration steps to finally get pure phosphate products.

There are two common processes in phosphate ore production lines.

Direct flotation is the use of effective inhibitors to suppress vein minerals and trapping agents to enrich phosphate minerals in froth, and can be applied to low-grade phosphate ores, including magmatic apatite and sedimentary metamorphic apatite ores.

Mainly used for the separation of phosphate ore and dolomite, flotation of dolomite with fatty acid trap in a weak alkaline medium, enriching phosphate minerals in the tank, the advantage of which is to achieve room temperature flotation, the coarse size of the product in the tank is conducive to product post-treatment.

Equipment commonly used in phosphate ore production lines include crushers, ball mills, leaching tanks, filters, dryers, etc. The selection and configuration of these equipment will be adjusted and optimized according to the nature of the ore, production process and production capacity. The production line also requires attention to product safety, especially in steps such as leaching and filtration, where measures need to be taken to prevent leakage and contamination of phosphate and other chemicals.

A phosphate ore production line is a special line for processing phosphate ore. It can process various phosphate ores, such as apatite, calcium phosphate, phosphorite, etc.

The advantage of the phosphate ore production line is that it can efficiently extract the elemental phosphorus from the ore, reducing the waste of natural resources, while achieving the recycling and reuse of waste. In addition, the production line is increasingly automated, which improves production efficiency and product quality, and reduces the impact of manual operations on the production environment and health.

As a professional mining equipment manufacturer, ZOOMJO has a wealth of experience and technical strength in the industry. We are committed to providing high quality mining equipment and excellent service to help our customers achieve efficient, safe and environmentally friendly production. If you have any needs for mining equipment, please feel free to contact us, we will be happy to provide you with a full range of technical support and quality products and services.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.