BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Silica sand is also known as quartz sand (SiO2 content greater than 98.5% for quartz sand, less than 98.5% for silica sand), silica sand washing generally through the process of quartz stone crushing, grinding, washing, classification, desliming, scrubbing, magnetic separation, flotation, drying and other processes, so that to remove a small or trace amount of impurities in silica sand, to get refined silica sand or high purity silica sand, used in glass, ceramics, construction, chemical industry, refractory materials and other industries.

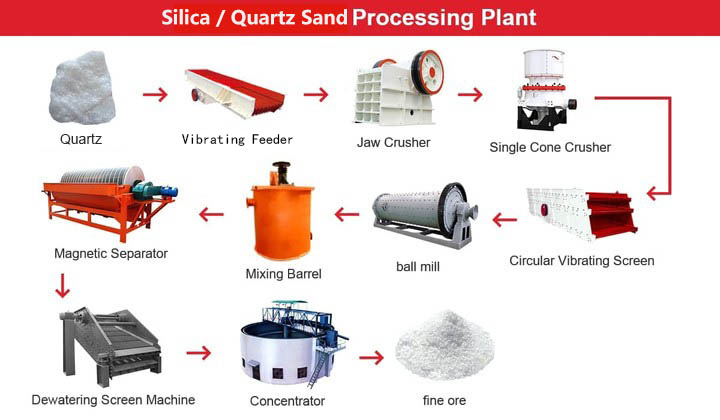

Silica sand / Quartz sand washing beneficiation process and equipment

Main Equipment: jaw crusher, ball mill, spiral sand washer machine, magnetic separator, dewatering screen, concentrator.

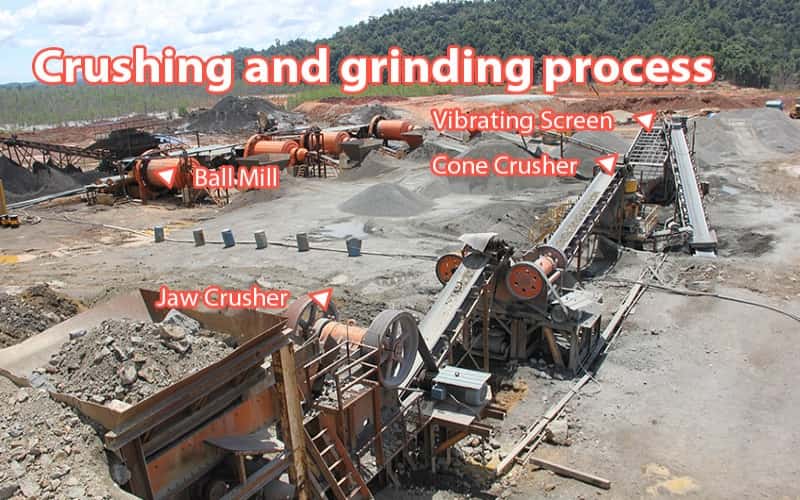

Stage 1, Silica sand / Quartz sand crushing process

Crushing: raw materials first into the jaw crusher for coarse crushing, feed size ≤ 1020mm, discharge size of 220-350 mm, and then fine crushing with cone crusher, so that the material discharge size ≤ 25mm.

Silica sand / Quartz sand crusher equipment: jaw crusher, cone crusher, hammer crusher, roller crusher, impact crusher.

Stage 2, Silica sand / Quartz sand grinding process

Grinding: Quartz blocks need to be crushed to 25mm and then ground to a certain size by rod mill or ball mill.

Quartz sand grinding discharges are usually between 40~120 mesh.

Stage 3, Silica sand / Quartz sand classification process

Washing and grading: the minerals can first be separated from the soil and impurities covering the surface of the quartz sand by trommel screen or scrubber, and then washed and separated by spiral sand washer machine and spiral chute.

Main equipment: trommel screen, spiral sand washing machine, wheel sand washing machine, spiral chute.

Stage 4, Silica sand / Quartz sand magnetic separation process

Magnetic Separation: Magnetic Separation is mainly used to remove magnetic minerals from silica sand. Generally speaking, common hematite, limonite, ilmenite, pyrite, pyroxene, black mica, etc. in silica sand can be removed by magnetic separation process.

Noteds: Magnetic separation is one of the commonly used processes in silica sand washing plant, the method is simple, low investment cost and high efficiency.

Flotation(optional): Flotation mainly removes feldspar, mica and other non-magnetic associated impurities in quartz sand. The purity can be increased to 99% through flotation. Commonly used flotation machine is SF flotation machine, BF self-priming mechanism mixing style flotation, inflatable mechanical flotation machine.

After flotation, the quartz concentrate can be dewatered by spiral sand washing machine to get the final high purity quartz sand, whose SiO2 content can be more than 99%.

Drying(optional): According to the actual production needs, the quartz sand after flotation can be further dewatered and dried, and then get quartz powder to meet different industrial needs.

Silica sand washing beneficiation plant /quartz processing plant price (cost)

Different capacity, different configurations of silica sand washing beneficiation plant price is different, if you are interested in silica sand washing beneficiation plant equipment, please tell us your needs, our engineers will customize the most suitable solution for you!

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.