BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Barite is an important non-metallic mineral resource, widely used in chemical industry, manufacturing, construction and other fields. Barite is brittle and fragile, with large tubular crystals. The mining and processing of barite is a systematic project, which requires the establishment of a complete set of beneficiation production line.

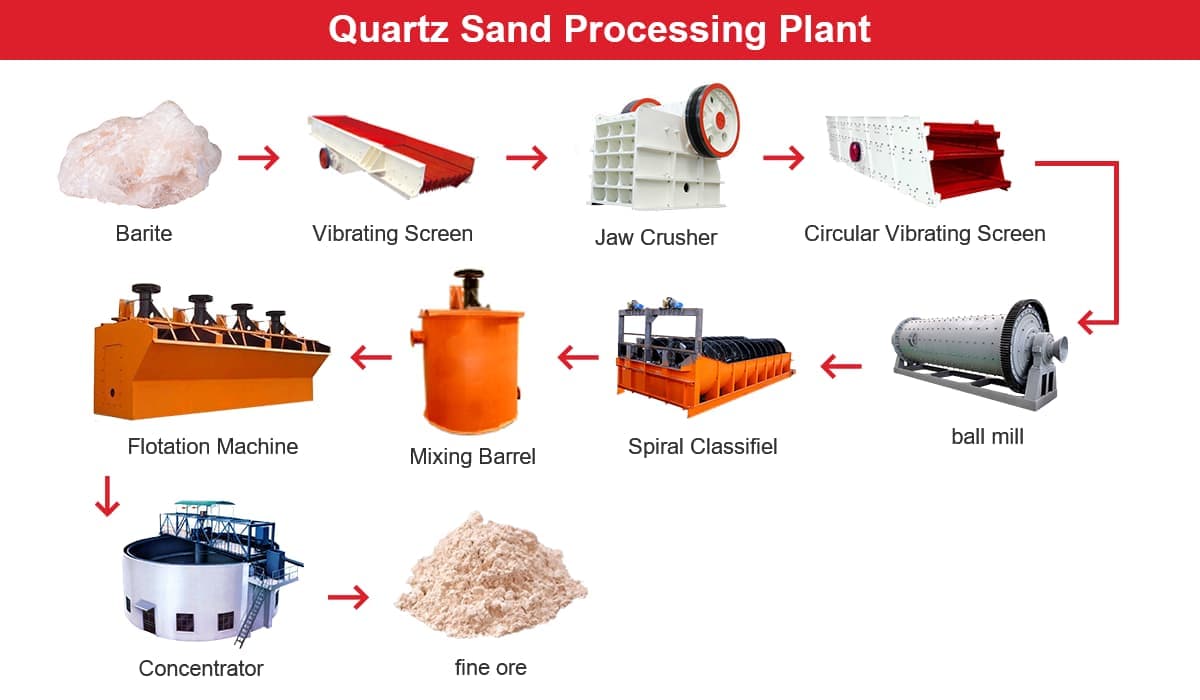

The process flow of barite beneficiation production line mainly includes four processes: crushing, sorting, washing, grinding and milling. The barite ore enters the crusher, and after crushing, the ore is broken into smaller particles for subsequent sorting. After sorting by electromagnetic sorter and air flotation sorter, the crushed ore is divided into products with different particle sizes, among which, the electromagnetic sorter can separate the magnetic materials in the ore and the air flotation sorter can separate the non-magnetic materials in the ore. After washing, the ore with larger particle size is washed out and the ore with smaller particle size is left for subsequent grinding and milling. Finally, the washed ore is ground and milled by the mill and powder mill to obtain ore products of different particle sizes.

The barite beneficiation production line mainly consists of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener and dryer and other main equipment, together with ore feeder, bucket elevator and tape transfer can form a complete beneficiation production line. The production line has the characteristics of high efficiency, low energy, high processing capacity and reasonable economy.

The advantage of barite beneficiation production line is that it can effectively separate the ore products with different particle sizes, and it has low energy consumption and little environmental pollution. Its disadvantage is that the equipment cost is high, the investment is large, and the operation is complicated and needs professional technicians to operate.

In the barite beneficiation production line, each link of equipment needs to work together to achieve efficient and stable operation of the whole production line. Reasonable equipment configuration, scientific process flow and efficient management control can ensure the efficient operation of barite beneficiation production line and realize the optimal development and utilization of ore resources.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.