BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

Iron ore is the main raw material for the steel iron production industry, but low-grade iron ore cannot be used in metallurgical plants, so it needs to be upgraded iron ore by increasing the iron content and reducing the chalcopyrite content

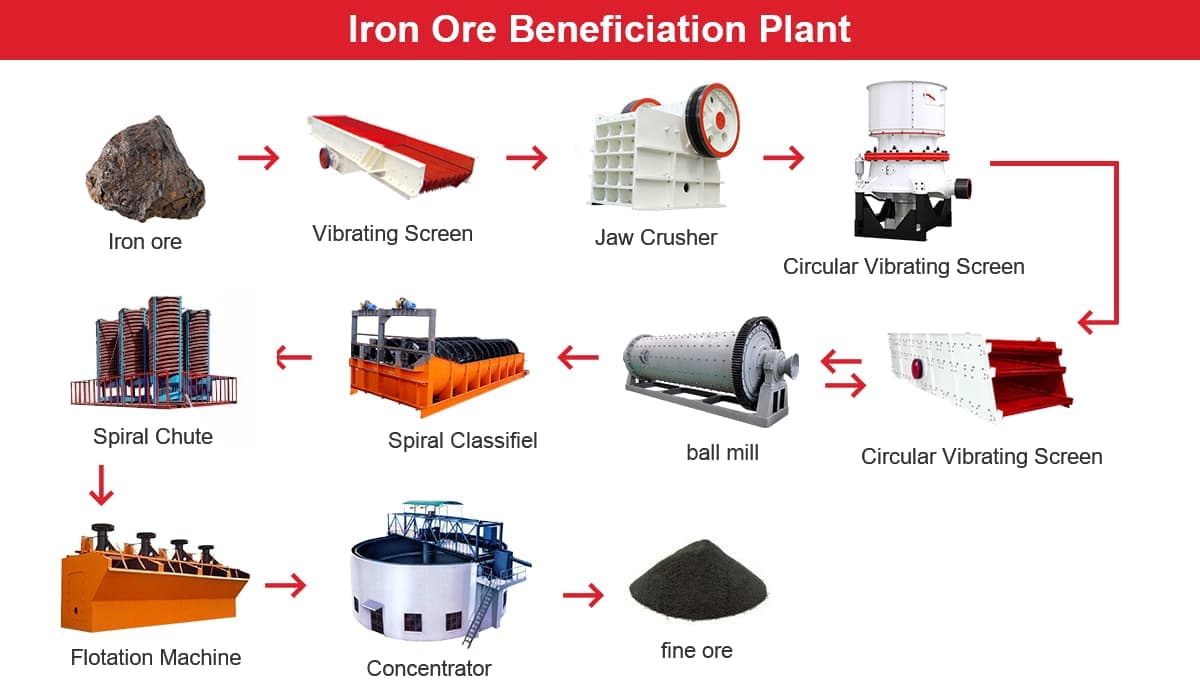

Iron ore beneficiation plant is process used to extract iron from iron ore, which can process many different types of iron ores, such as: hematite, limonite, mirror iron ore and other weak magnetic iron ore. The iron ore separation process can be applied to hematite ore and impurities can not be uniform in size and fine grain content, also includes a small amount of magnetite, vein minerals containing quartz, kaolin and other ore nature is more complex hematite. In this process, the ore undergoes a series of processing and separation, and finally obtains high-grade iron ore concentrate products. The beneficiation plant cost is low, high efficiency, and no pollution to the environment.

The production process of iron ore beneficiation plant generally includes the following steps: crushing of raw iron ore, screening, gravity separation, magnetic separation, flotation, drying and refining, etc. Among them, magnetic separation is the most critical step, through which the magnetic material in the iron ore is separated out and the high-grade iron ore concentrate products are finally obtaine.

Due to the different chemical properties of iron ores, the beneficiation methods are also different.

1.Magnetic separation of iron processing plant

Magnetic separation is the use of magnetic fields to separate materials with different magnetic field strengths. Magnetic separation is the most popular method used for beneficiation of ferrous metal ores. There are two types of magnetic separation: ordinary magnetic separation and high density magnetic separation. Ordinary magnetic separation is used for sorting magnetite. High density magnetic separation is used to sort hematite and other weakly magnetic ores.

2.Flotation of iron processing plant

The flotation process is also common in today's iron ore beneficiation. It has become a very important way to recover weakly magnetic ores. It is also used to process iron ore fines to reduce silica and impurities

3.Gravity separation of iron processing plant

Gravity separation separates fractions of ore with different densities. Gravity separation is also one of the most popular methods of beneficiation. It is widely used for beneficiation of heavy metal ores, especially weakly magnetic iron ores.

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.