BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

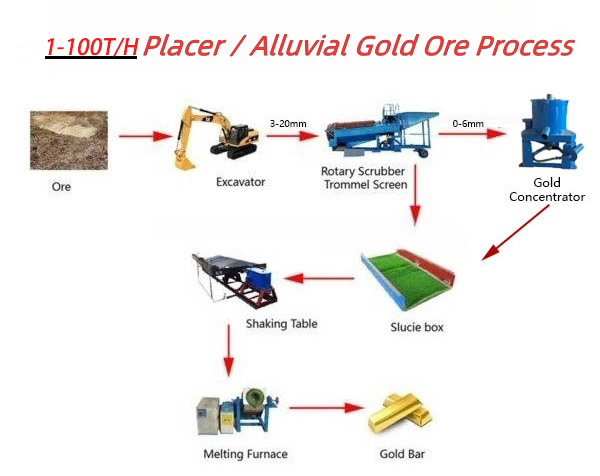

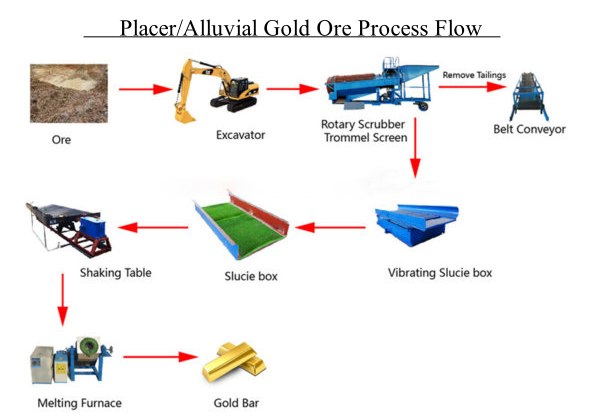

Commonly used gold mining equipment gold ore processing plant process(low investment, high result)

Stage 1: Crushing + Screening Process

1. Gold ore crushing equipment (jaw crusher / cone crusher): crushing large ore into smaller particles, so that the particle size of the ore reaches 25mm or less, which is convenient for subsequent processing.

2. Classifier(Vibrating Screen / Trommel Screen): Screens and classifies the ore slurry after milling, classifying it into particles of different sizes.

Stage 2: Grinding Process

3. Ball Mill: Used for further fine grinding of the ore to powder, according to the need to grind the ore size to 74μm (-200 mesh) 50% ~ 80% of the best, in order to subsequent beneficiation operations.

Stage 3: Beneficiation Process

4. Jig & Shaking Table: Used to carry out reclassification operations on ores to achieve separation and beneficiation based on the difference in particle densities.

5. Flotation Machine: Separation and beneficiation of minerals is achieved through the attachment of air bubbles to specific mineral particles in suspension.

6. Magnetic Separator: Using the magnetic difference of minerals in the ore, the ore containing magnetic minerals are sorted and extracted.

Stage 4: Concentrating process

7. Concentrator and dryer: using the gravity of solid particles, concentrator precipitates gold concentrate, separating the solid from the liquid, and then using the dryer to dry it, finally achieving a water content of ≤ 20%.

Hot sale gold mining equipment types

Chat Online

Chat Online

Main Gold Ore Beneficiation Processing Methods and Equipment.

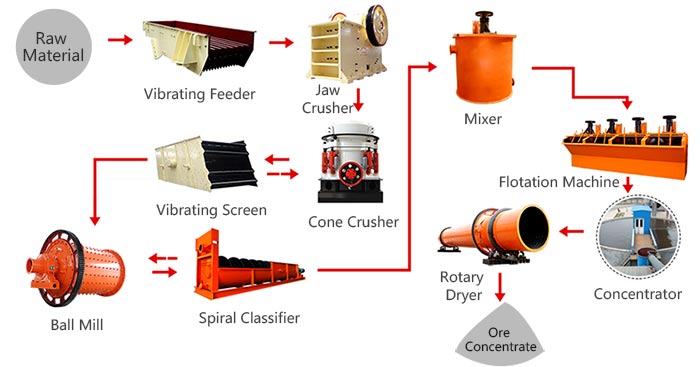

一,Flotation gold ore processing

The flotation method is a widely used beneficiation method in rock gold mines. 80% of rock gold mines use this method for gold beneficiation, with recovery rates as high as 90-97%, and the gold concentrate selected can be sent to smelters for smelting.

Main equipment: jaw crusher, vibrating screen, ball mill, spiral classifiel, flotation machine, etc.

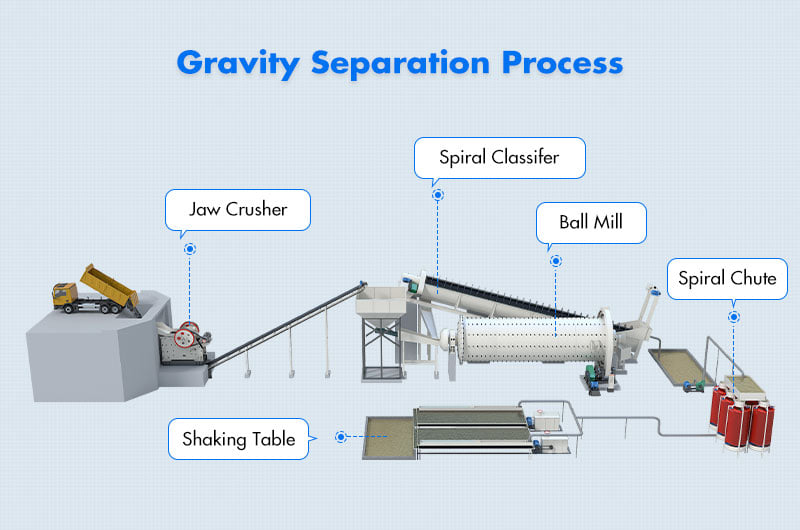

二, Gravity separation gold ore processing

Gravity Separation Gravity gold separation is based on the density of gold ore, widely used in alluvial gold mining, placer gold mining, hard rock gold mining, with small investment, large processing capacity, simper operation and high effiency.

Main equipment: jaw crusher, vibrating screen, ball mill, trommel screen, shaking table, jig, spiral chute, etc.

If you are interested in our gold ore processing equipment, please feel free to consult online. We will send you detailed gold ore processing solution flow and equipment list at the first time!

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.